Stoke Space selects Solukon for depowering additively manufactured rocket engine parts

April 2, 2024

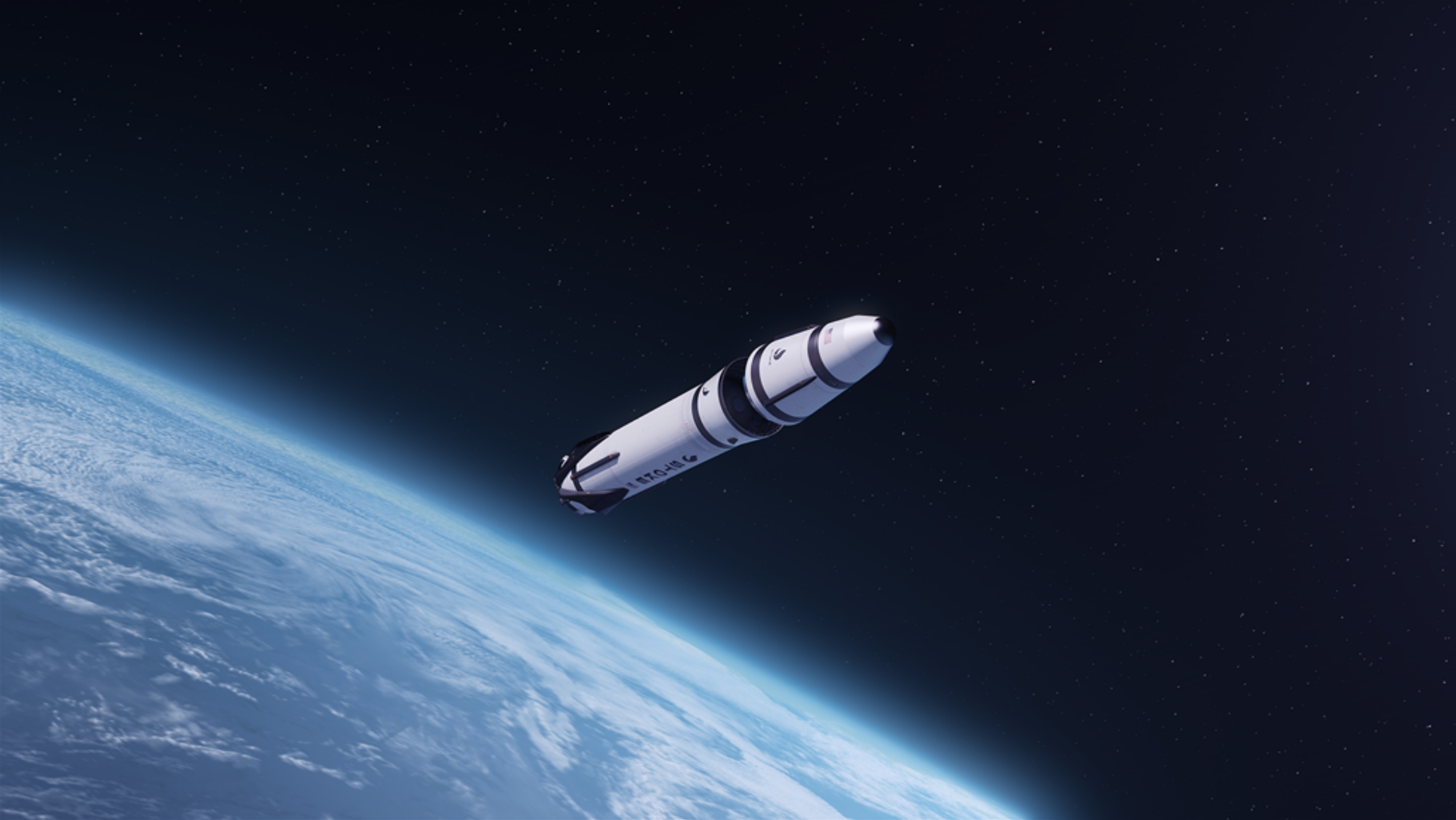

Stoke Space, a space launch company located in Kent, Washington, USA, is building what it claims is the world’s most efficient fully and rapidly reusable rocket designed to fly daily. Stoke’s rocket is expected to radically increase access to space opening the space economy for new and innovative technologies.

Stoke Space designs and additively manufactures copper thrust chambers which present an exceptional depowdering challenge. For this, Stoke has selected Solukon’s SPR depowering technology, having acquired an SFM-AT800-S.

Thrust chambers with complex inner structures

Both Stoke’s first and second stages are fully reusable. The second stage, usually thrown away in the conventional space industry, is able to reenter Earth’s atmosphere and land after deploying payloads in space. To enable rapidly reusable vehicles, both of Stoke’s first and second stage engine thrust chambers are additively designed and manufactured in-house. These thrust chambers feature regenerative cooling channels and built-in manifolds, features which are typically difficult to depowder.

The SFM-AT800-S is Solukon’s flagship machine for tough depowdering challenges and is reportedly the most widely used automated powder removal system in the Additive Manufacturing industry. The SFM-AT800-S can handle metal parts with maximum dimensions of 600 x 600 x 600 mm (alternatively: 800 x 400 x 550 mm) weighing up to 300 kg. Based on Solukon’s Smart Powder Recuperation technology SPR, the SFM-AT800-S uses targeted vibration and unlimited two-axis rotation in a protected atmosphere to get unfused powder out of metal laser melted parts fully automatically.

High frequency knocker for copper applications

Stoke additively manufactures its thrust chambers using a special copper alloy with a high conductivity in an effort to enable maximum reusability. Copper powder, however, makes complete powder removal more challenging due to its tendency to stick and clump within the tight regen channels. Stoke uses a high-frequency knocker provided as an add-on in the Solukon machine to loosen trapped copper powder bulks from internal channels of the parts. Stoke also applies an ultrasonic vibration system to enhance the flow of the copper powder, which is directly connected to the component.

For complex geometries there’s another way to optimise depowdering even further – by analysing the CAD file of the part. The unique Solukon depowdering software SPR-Pathfinder does so: it works with a digital twin of the part and calculates the motion pattern for the Solukon system automatically to get the powder out of the complex structures.

“SPR-Pathfinder is a convenient tool to optimise the depowdering before it even started,” said Andreas Hartmann, CEO and CTO of Solukon.

“We chose Solukon for their industry leading capability in automating depowdering of complex parts,” shared Zach Sander, Head of Engine and Fluid Systems at Stoke Space. “Regeneratively cooled rocket engine thrust chambers are notoriously difficult to depowder, and we wanted to ensure we had a robust machine to reliably depowder these difficult copper components.”

Download Metal AM magazine