SSI Sintered Specialties changes name to DSB Technologies

May 3, 2022

SSI Sintered Specialties, LLC, a manufacturer of sintered metal components headquartered in Janesville, Wisconsin, USA, has changed its name to DSB Technologies. Following an extensive re-brand, the name change is intended to build on the company’s recent technology expansion, which has seen investment in Powder Metallurgy, Metal Injection Moulding (MIM) and metal metal Binder Jetting (BJT) Additive Manufacturing technologies over the last year.

“This organisation has an impressive history and an even brighter future ahead,” stated Paul Hauck, COO of DSB Technologies. “From the earliest days, we have operated with a drive for innovation. As our company and customer base continues to evolve, this rebranding embodies our commitment to the growth needed to be a prominent manufacturing partner.”

For over forty years, DSB Technologies has collaborated with its customers as a metallurgical solutions partner for high performance Powder Metallurgy components. Under the name SSI Sintered Specialties, it operated as the sintered components division of a successful precision engineering organisation led by the company’s current ownership. In 2019, SSI Sintered Specialties was separated from the organisation and took the opportunity to leverage its existing capabilities and expand the business into new technologies, applications, and markets.

“SSI was historically known as a conventional press and sinter business, but there is so much more at the core of our company,” Hauck added. “Our new company name allows us to adopt new technology more freely and bring to light to the industry-leading talent and vast expertise we offer to our customers.”

With a committed focus on growth, DSB Technologies is reportedly combining its present Powder Metallurgy and manufacturing knowledge with new technology and talent investments to continue designing and engineering complex, functional, PM components.

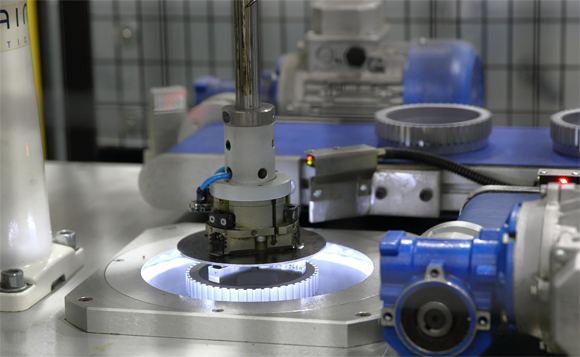

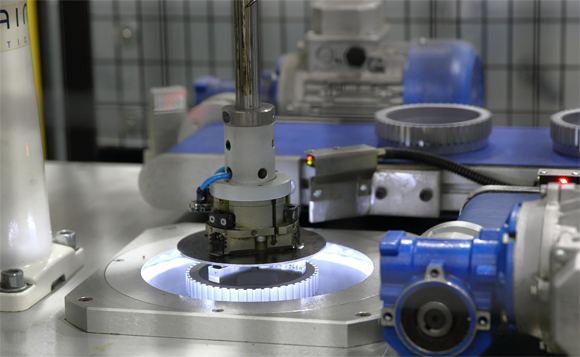

The company houses what is believed to be North America’s largest capacity of high temperature sintering furnaces in its 23,226 m2 facility in Janesville, along with a fleet of over thirty-five presses, a vast range of secondary operations, a hands-free moulding cell and an in-house automation team.

In the December 2021 issue of Powder Injection Moulding International, we report on a visit to SSI Sintered Specialties. Read the full article here