Solukon and Reichenbacher automate unpacking and depowdering in PBF-LB process

July 25, 2023

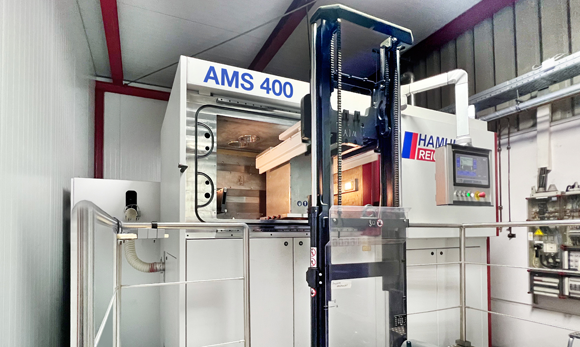

Solukon, Augsburg, Germany, has partnered with Reichenbacher Hamuel GmbH, Dörfles-Esbach, Germany, to produce an automated solution for the unpacking and depowdering of parts produced via Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing.

After the PBF-LB process, the built part is in a ‘powder cake’ of unused metal powder in a container. To unpack the part, the powder must be vacuumed and cleared away. Once the part is uncovered and removed from the container, it is placed in a Solukon system to automatically remove any unfused metal powder from the interior of the part.

Programmable two-axis rotation and vibration are used to make the powder fluid and allow it to flow out of the interior channels in a controlled manner. This is the typical method for removing powder from complex laser-melted metal part; the Reichnenbacher-Solukon project combines these two process steps into an automated system for the first time.

It is essential to the Reichenbacher-Solukon project that the entire container, in which the part sits, is loaded into the SFM-AT1000-S. The Reichenbacher box, which has a removable bottom and sides, is secured using a zero-point clamping system. It is then rotated upside-down, and the first of the loose powder from the powder cake is emptied automatically. The discharged powder is fed directly into an external material preparation station.

Next, the user removes the box frame with an external mobile lifting device or crane, so that the part is fully accessible. The short swivel arm version of the Solukon system then cleans the part as usual using what is described as ‘one-of-a-kind SPR technology’ with programmable two-axis rotation and adjustable vibration. The motion sequence in the Solukon system can reportedly be calculated in advance easily and automatically using the part’s CAD file when using the SPR-Pathfinder software.

According to reports, the SFM-AT1000-S can accommodate boxes of up to 800 kg and, with the help of a high-frequency knocker, can loosen even stubborn powder clumps in the part’s interior channels.

“The SFM-AT1000-S with box unpacking is a project with a high degree of automation. Furthermore, it demonstrates how flexibly our systems can be used for individual customer solutions. We are happy to support Reichenbacher in their project unpacking boxes of laser-melted metal parts. This is how, together, we create a real competitive edge for Reichenbacher’s customers,” shared Andreas Hartmann, CEO and CTO of Solukon.

“With Solukon, we once again have a system in our portfolio that has a truly unique selling point and makes us stand out in the area of post-processing against standard solutions on the AM market. This puts Reichenbacher in a position to map the entire 3D printing process chain. We thank Mr Hartman and team for their openness and fast execution of the project,” added Dr Kawalla-Nam, Head of Additive Manufacturing Technology at Reichenbacher.

The SFM-AT1000-S has reportedly already passed its box unpacking field test and a leading manufacturer of steel moulds is said to be using the system and has been for the past few months.

The SFM-AT1000-S for combined unpacking and depowdering is now available from Reichenbacher. Solukon is participating as system vendor.

Download Metal AM magazine