SLM Solutions enables world’s largest metal additively manufactured rocket engine

February 11, 2019

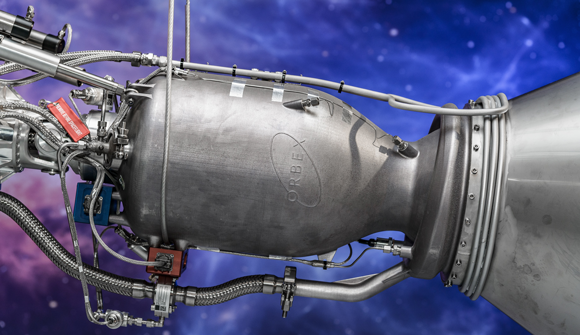

The Prime rocket is said to be the largest metal AM rocket engine ever produced (Courtesy Orbex)

Spaceflight company Orbex, Forres, Scotland, has produced what it states is the world’s largest metal additively manufactured rocket engine. The engine, developed for the company’s Prime rocket, was produced in a single piece on an SLM®800 system from SLM Solutions AG, Lübeck, Germany.

Founded in 2015, Orbex develops small satellite launch vehicles and introduced the Prime rocket at the opening of their new Forres headquarters. The launcher, designed to deliver small satellites into Earth’s atmosphere, is said to use 100% renewable fuel, cutting carbon emissions by 90%, and employs a novel zero-shock staging and payload separation, resulting in zero orbital debris.

By optimising its design for metal Additive Manufacturing, the company was able to create a structure which it reports is 30% lighter and 20% more efficient than any other launch vehicle in its category. Orbex’s aerospace engineers partnered closely with the applications engineering team at SLM Solutions during the design process to ensure a successful build. Lukas Pankiewicz, Applications Specialist, headed the consulting team inside SLM Solutions to develop a unique set of parameters optimised for the rocket’s geometry.

Alongside the Orbex design team, Pankiewicz consulted on the various design features and orientation options while ensuring the part built successfully with the required material properties and dimensional accuracy. “Our aim during the process was to fulfil the quality expectations of the Orbex team, keep the functionality of the part and make it suitable for additive manufacturing,” he explained. “Every single support structure used in data preparation has been customised to obtain the best quality in every section of the engine, taking post-processing into consideration as well.”

The SLM 800 is a large-format metal AM system, featuring a 260 x 500 mm powder bed that can build parts up to 800 mm tall. This allowed the Prime engine to be built in a special nickel alloy in a single piece. Further, the SLM HUB unpacking system for the SLM 800 integrates contactless powder handling and automated build chamber conveyors, to transfer the finished part to an unpacking station designed to remove powder through vibration and rotation.

Pankiewicz ensured a powder removal strategy was incorporated into the build with purpose-driven delivery channels to be certain as much powder was removed from the build as possible, while reducing material loss. After production, reference samples built together with the engine were analysed in the SLM Solutions’ metallography lab, where porosity level and distribution were proven to meet the quality acceptance criteria.

The rapid iteration times inherent to the SLM process allowed Orbex to realise both time and cost reductions – saving 90% in turnaround time and over 50% in costs compared to traditional CNC machining production. “This has always been what SLM Solutions is about,” stated Dr Axel Schulz, Chief Sales Officer, SLM Solutions. “Members of our team helped invent the Selective Laser Melting technology!”

“We’ve always wanted that technology to succeed – which isn’t just about selling SLM machines but creating that paradigm shift for the customer to be successful with their process,” he continued. “SLM Solutions consulted Orbex on how to make the technology best work for them and transferred that knowledge to ensure their successful implementation as they ramp up to production.”

Jonas Bjarnoe, Chief Technology Officer, Orbex, stated, “The SLM Solutions team showed true dedication and in-depth knowledge of our work. I’m looking forward to continuing this collaboration in 2019 and onwards. Orbex and SLM Solutions have solved some important puzzle pieces which will change the space business.”

Orbex has received £30 million ($40 million) in public and private funding from sources including the U.K. Space Agency (UKSA) and venture capital firms Sunstone Technology Ventures and the High-Tech Gründerfonds, as well as strategic investor Elecnor Deimos Space, the European Space Agency (ESA) and the European Commission Horizon 2020 programme. Its staff have professional backgrounds within NASA, ESA and other spaceflight organisations.