Sintavia introduces high-powered CT scanning services

February 16, 2017

CT scanning will complement Sintavia’s metallurgical analysis, AM in-situation monitoring and metrology expertise

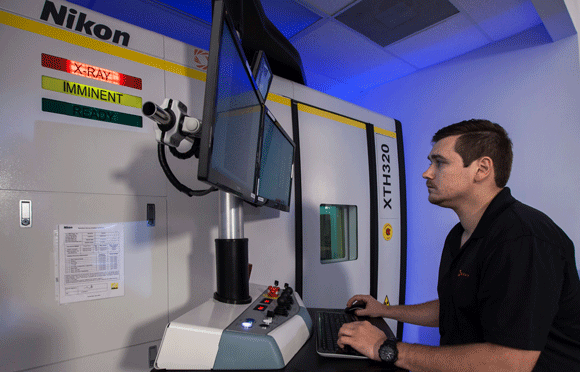

Sintavia, LLC, based in Florida, USA, has announced that it has broadened its precision scanning and quality control services for critical industries by incorporating high-powered Computed Tomography (CT) scanning capabilities.

The company’s Nikon XTH 320 CT scanner offers porosity analysis as well as nondestructive examination of the complex internal networks of additively manufactured components. By adding an industrial CT scanner with multiple kilovolt (kV) X-ray sources, Sintavia claim to be one of very few companies with the capability to confirm quality and ensure the material integrity of AM parts manufactured for aerospace and defence applications.

“Quality control is the number one reason Sintavia incorporated the CT scanner in our manufacturing process,” stated Doug Hedges, Sintavia’s President and COO. “Adding this high-fidelity scanner to our comprehensive manufacturing and testing suite allows us to meet and exceed customer quality specifications.”

Sintavia’s industrial CT scanner features 225 and 320 kV microfocus X-ray sources that are used depending on the density of material and resolution necessary to analyse internal passages and cooling channels. The 225 kV source is equipped with a reflection target creating a 3 micron spot size which allows Sintavia to generate extremely detailed imaging for aluminium and titanium parts. The 320 kV source is used to penetrate through larger parts or higher density alloys such as nickel alloys and stainless steel with high resolution and magnification.