Simufact announces next generation of its Additive Manufacturing simulation software

November 15, 2018

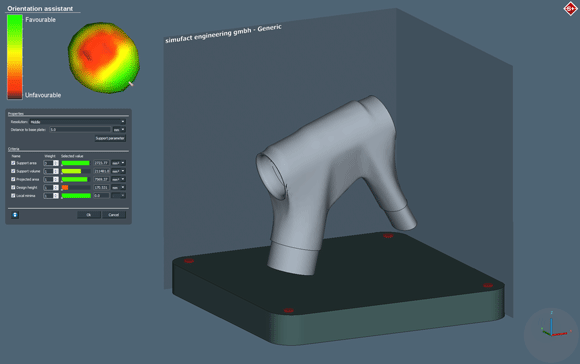

Simufact Additive 4’s orientation assistant helps to determine the best build orientation (Source NDES)

Simufact, an MSC Software Company, headquartered in Hamburg, Germany, has announced Simufact Additive 4 – the next generation of its solution for the simulation of metal Additive Manufacturing processes.

Simufact Additive is reported to be a scalable, practitioner-oriented simulation solution predicting distortion, stress, and temperature effects. The software helps optimising build preparation, build simulation and subsequent steps in the AM process chain, including heat treatment, cutting the base plate, removing supports and Hot Isostatic Pressing (HIP).

“Our new version 4 underlines our ambitions to provide the best overall process simulation package – concerning speed, accuracy, functionality, and usability,” stated Dr Gabriel Mc Bain, Simufact´s Senior Director Product Management.

“The software comes with a workflow-oriented user interface, which our customers report as the best-in-class GUI,” added Dr Patrick Mehmert, Product Manager Additive Manufacturing. “We will further strengthen our ease-of-use approach with new functionality available in Simufact Additive 4, which efficiently guides the user through the simulation process workflow and supports him with new automation and assistant functionalities.”

The software helps to identify the best build orientation, predict and completely compensate final part distortion automatically below a given threshold, optimise support structures automatically, identify overheated or not sufficiently heated zones and predict manufacturing issues such as cracks, shrinklines, and recoater contact – before they occur.

It was stated that users can now consider the effects of pre-heated base plates or build spaces and can achieve more accurate simulation results for fully nested base plates and build spaces.

Support structures play a significant role in achieving first-time-right print results. Simufact Additive offers integrated support structure capabilities, based on Materialise’s expertise, which allows users to visualise the support structures and perform basic operations, such as adjusting the density and angle of the supports.”

Another focus point for the new release is to strengthen the process chain capabilities. “Our open software concept allows interfacing with third party solutions in the AM process chain, such as OEM build preparation software – Renishaw´s QuantAM is an example – and Materialise Magics,” Mc Bain added.