Sigma Labs and AMFG collaborate to optimise Additive Manufacturing workflow

March 22, 2022

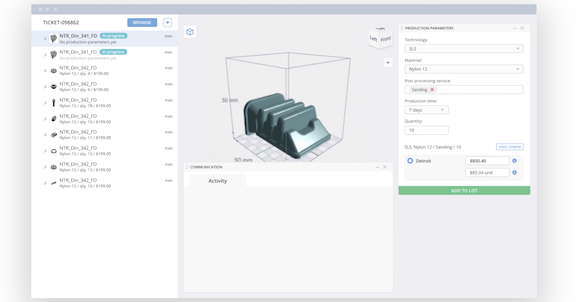

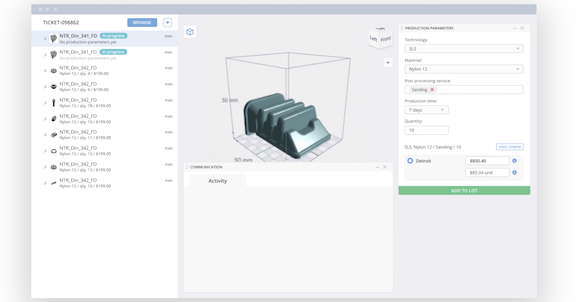

Sigma Labs, Inc, Santa Fe, New Mexico, USA, has signed an agreement with AMFG, London, UK, that will enable the combination of AMFG’s manufacturing execution systems (MES) software and Sigma’s in-situ monitoring. The move is expected to allow users to automate their full production workflow, move towards automated part and process qualification, capture data to support simulation and predictions, decrease post-inspection needs and provide connectivity through the entire Additive Manufacturing process.

“While there are point solutions that solve specific challenges, everyone benefits when data between systems flows freely and is used to optimise the entire process,” stated Sven Hinrichs, Global Head of Technical Consulting, AMFG. “We’ve been great admirers of the tremendous strides Sigma Labs has made in ensuring part quality and qualification and are very happy to partner with their team to integrate for customers into an optimised end-to-end solution.”

Jacob Brunsberg, president of Sigma Labs, added, “We chose to partner with AMFG because of their solid reputation in the manufacturing execution space. Like Sigma Labs, AMFG is committed to deep collaboration that benefits individual customers, as well as the Additive Manufacturing industry as a whole. The focus has shifted in the past several years from developing technology for technology’s sake, to solving the end user’s business problem. Both of our companies are industry leaders in embracing this trend.”

Both Brunsberg and Hinrichs will present details of these joint solutions at the Additive Manufacturing Users Group (AMUG) conference, which will be held in Chicago, Illinois, USA, April 3–7, 2022. The session, entitled Connected AM Workflow: Powder-to-Part, will be held on April 5 at 3:00 PM. Sigma Labs and AMFG intend to discuss the importance of actionable data insights, as well as how to employ data meaningfully.