Scientists use machine learning to assess quality of additively manufactured metal parts

March 22, 2022

Scientists from Nanyang Technological University (NTU), Singapore, have developed what they state is a fast, low-cost imaging process that can analyse the structure of additively manufactured parts and offer insights into the quality of the material.

Until now, analysing the microstructure in additively manufactured metal alloys has been achieved using scanning electron microscopes, which can be costly and time-consuming to operate. The method, designed by Nanyang Assistant Professor Matteo Seita and his team, is said to provide the same quality of information in a matter of minutes by using a system consisting of an optical camera, a flashlight and a notebook computer that runs a proprietary machine-learning software developed by the team. The hardware is reported to cost around $18,500.

The new process begins by treating the specimen’s surface with a chemical reagent; this allows the team to view the microstructure. The specimen is then placed in front of a camera, whereupon multiple images are taken while the specimen is illuminated from multiple angles using the flashlight. The software then performs an analysis of the light reflected from the metal crystals and determine their orientation. The entire process is reported to take about fifteen minutes to complete.

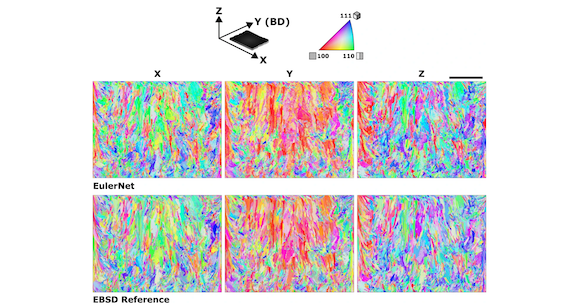

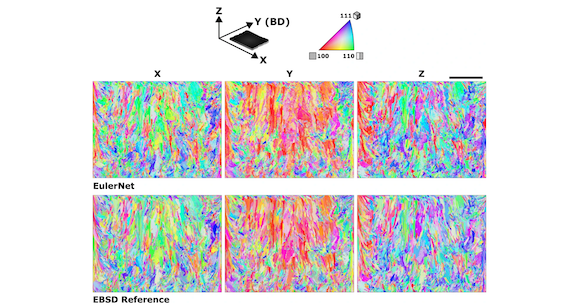

Because of the software’s machine learning capability, it was eventually able to predict the orientation of crystals based on the way light scatters off the surface of the metal. Based on this, the team was able to create a complete crystal orientation map that provides comprehensive information about the crystal shape, size and atomic lattice orientation.

“Using our inexpensive and fast-imaging method, we can easily tell good 3D-printed metal parts from the faulty ones,” Seita explained. “Currently, it is impossible to tell the difference unless we assess the material’s microstructure in detail.”

The findings of the team’s work has been published in npj Computational Materials. The full paper ‘A machine learning approach to map crystal orientation by optical microscopy,’ authored by Mallory Wittwer and Matteo Seita, is available here.