Sciaky’s EBAM process reaches deposition high during MAMA project

June 14, 2022

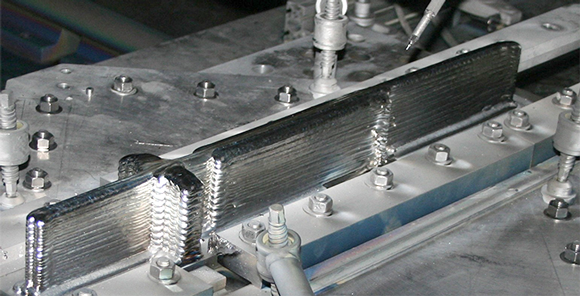

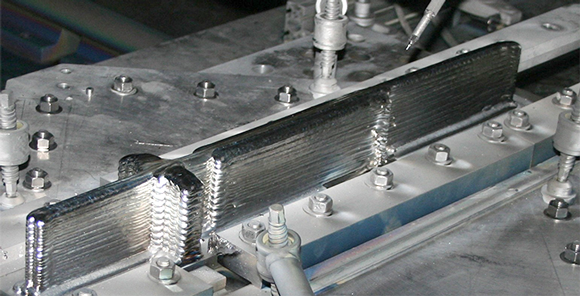

Sciaky Inc., Chicago, Illinois, USA, a subsidiary of Phillips Service Industries, Inc. (PSI), reports that its Electron Beam Additive Manufacturing (EBAM®) technology, a wire-based electron beam Directed Energy Deposition (DED) process, has reached deposition speeds of 18.14 kg per hour. The company claims this is world’s highest/fastest deposition rate for industrial metal Additive Manufacturing.

The Saint Exupéry Institute for Research in Technology (IRT) based in France, achieved EBAM’s high deposition rate (HDR) while working on the Metallic Advanced Materials for Aeronautics (MAMA) project which was launched in 2019. One of MAMA’s initial goals was to combine die forging with metal Additive Manufacturing to develop a new process for manufacturing titanium aircraft parts.

To date, Sciaky’s EBAM technology has deposited over 150 kg of titanium for three different MAMA applications. Airbus and Aubert & Duval also participated as key process contributors for this particular initiative of the MAMA project.

“Sciaky is excited about EBAM’s new deposition rate milestone,” stated Scott Phillips, president and CEO of Sciaky, Inc. “We are committed to discovering new applications for EBAM that will help manufacturers save significant time and money on part production, as well as improve part quality.”

Sciaky explains that its EBAM machines are capable of producing parts up to 5.79 meters in length and unite quality and control with IRISS®, the Interlayer Real-time Imaging and Sensing System, which the company states is the only real-time adaptive control system in the metal AM market that can sense and digitally self-adjust metal deposition with precision and repeatability.