Metallic Advanced Materials for Aeronautics project coupling traditional metallurgy with wire-fed metal AM

July 2, 2019

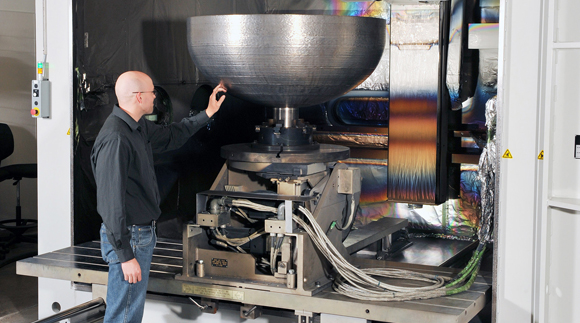

A 116 cm diameter dome for a satellite fuel tank produced on a Sciaky EBAM 110 machine, pictured here at Lockheed Martin’s space facility in Denver, Colorado, USA (Courtesy Lockheed Martin)

Sciaky, Inc., a subsidiary of Phillips Service Industries, Inc. (PSI), headquartered in Chicago, Illinois, USA, has entered into an R&D initiative with Aubert & Duval, Paris, France, and Airbus, headquartered in Leiden, the Netherlands, driven by the Saint Exupéry Institute for Research in Technology (IRT), Toulouse, France. The Production Engineering laboratory of the National School of Engineering in Tarbes, France will serve as an academic partner for this project, which is titled Metallic Advanced Materials for Aeronautics (MAMA).

The goal of the project is to couple traditional metallurgy (high-power closed die forging) with wire-fed metal AM (in this case, Sciaky’s Electron Beam Additive Manufacturing (EBAM®) process) to develop new manufacturing processes for titanium alloy aircraft parts. In its first phase, the project has a global funding of €4.2 million (just under $4.8 million), of which 50% comes from the French State as part of its ‘Investing in the Future’ programme, and the other 50% from industrial partners.

Scott Phillips, President and CEO of Sciaky, Inc., stated, “Sciaky is proud to work with the Saint Exupéry IRT, Aubert & Duval and Airbus on this exciting project. Industrial metal Additive Manufacturing technology continues to break new ground every day, and Sciaky is committed to keeping EBAM at the forefront of this movement.”