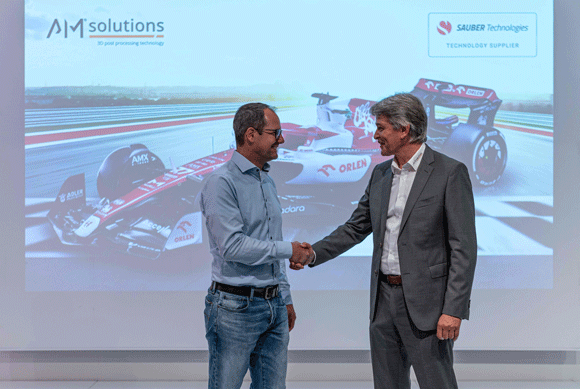

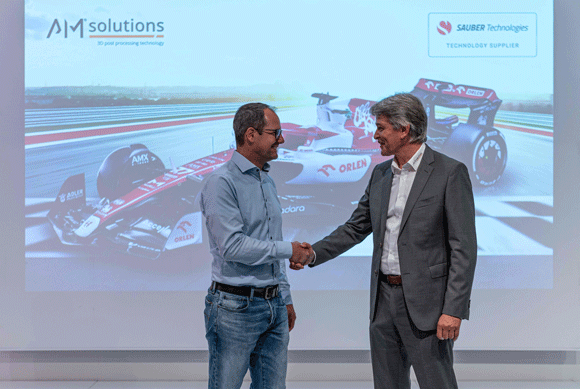

Sauber Technologies and AM Solutions extend partnership

November 9, 2022

AM Solutions – 3D post processing technology, headquartered in Untermerzbach, Germany, a brand of the Rösler Group, has announced that it has extended its partnership with Sauber Technologies for an additional two years.

Automated post-processing of additively manufactured parts is said to be essential to Sauber Technologies for the economical production of repeatable and high-quality parts, especially on an industrial scale. Over the last year, the company benefited from Rösler’s experience in surface finishing, by using post processing equipment provided by AM Solutions. Several additively manufactured parts have also been featured on the Alfa Romeo F1 Team ORLEN C42.

Under AM Solutions, the Rösler Group groups all activities related to Additive Manufacturing with a range of products and services, including systems, consumables and process engineering for the series-ready and automated post-processing of additively manufactured parts. Rösler’s experience in surface finishing in a real production environment as well as its own mechanical engineering is said to form a strong backbone of AM Solutions’ offerings.

As part of the relationship between Sauber Technologies and AM Solutions, the two partners are currently collaborating in the field of stereolithography in post-processing, to develop solutions to maximise the efficiency of the cleaning process and support removal. In addition, Sauber Technologies is already using several mass finishing and shot blasting machines from AM Solutions.

Christoph Hansen, COO Sauber Technologies, stated, “Over the past year, the partnership with AM Solutions has been of fundamental importance, as several business practices of our Group have been employing them, from the wind tunnel models to the most experimental components, and, of course, our Formula One cars. AM Solutions have brought its excellent experience and solutions to Sauber Technologies, helping us create 3D printed parts faster and in a more efficient way, two essential qualities for an ever-evolving business like ours. I am glad to be extending our partnership with the Rösler Group, and I am already looking forward to seeing what else we could achieve together in the future.”

Volker Löhnert, Managing Director of Rösler Oberflächentechnik GmbH, commented, “The extension of our partnership with Sauber Technologies is an important milestone for AM Solutions – 3D post processing technology. The team has a long tradition of using additively manufactured components in its Formula One cars and has been therefore interested in exploring the vast opportunities that 3D printing offers in terms of design, material selection, and lightweight construction. High-quality and repeatable post processing is of great importance for the optimisation of the entire process chain, and that is where we bring our decades of expertise in surface finishing, together with our customised solutions developed specifically for the peculiarities of AM-manufactured parts. For these reasons, we have the perfect partner at our side in Sauber Technologies.”