Safina defines green laser exposure parameters for copper on Prima Additive machines

October 11, 2023

Established in 1860 and based in Vestec, Czech Republic, Safina has a long tradition in the complex processing and manufacture of products from precious and nonferrous metals. Among other areas, Safina is a well-known supplier of gas atomised non-ferrous materials for Additive Manufacturing.

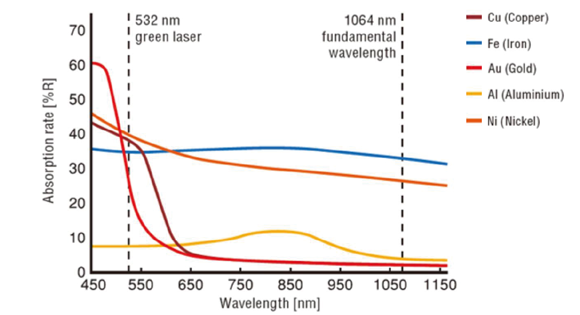

In the last few years, Safina has focused on materials development with Additive Manufacturing technology manufacturers. Recent projects include the development of process parameters for Prima Additive machines equipped with a 532 nm wavelength laser (known as the green laser). These are suitable for melting highly reflective materials such as pure copper or copper alloys. Unlike some competitors, the Prima Additive system uses a green IPG laser with a very small spot size.

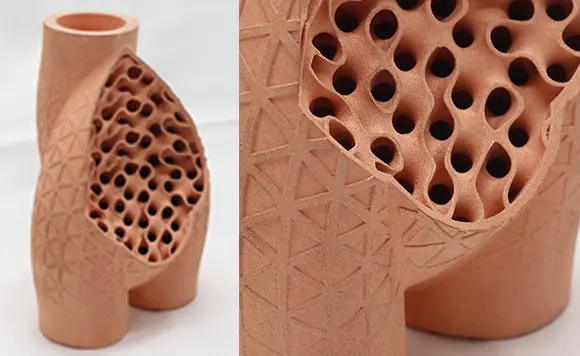

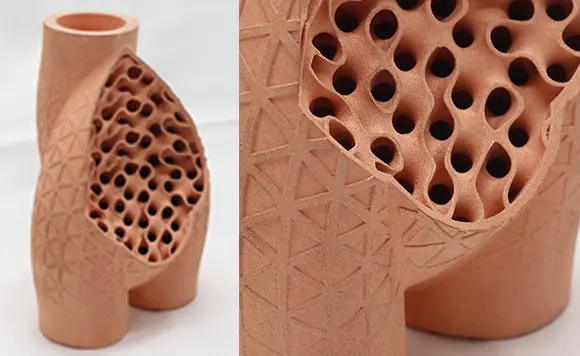

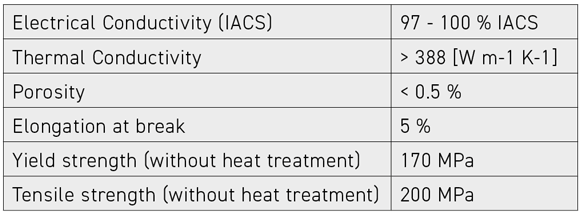

Using relatively standard pure copper with PSD -15-45 and purity of 99.95% and higher, smaller parts with complex, highly detailed geometries can be produced while maintaining thermal and electrical conductivity at the level of conventionally produced pure copper. In terms of numbers, this means thermal conductivity at 388 [W m-1 K-1] and electrical conductivity at 97-100% IACS across the build chamber. As a result, even on a machine with a relatively small chamber, parts can be produced that find use in industrial applications such as smaller heat exchangers or smaller induction hardening coils.

Depending on the type of application, it is possible to decide whether or not to apply heat treatments to fabricated parts, unlike copper alloys. Homogenisation annealing at high temperature will allow any defects to be eliminated, but the properties of the copper will change to some extent and a change in the mechanical properties of the copper must be taken into account (eg, yield strength is reduced by about 30-40 Mpa compared to untreated copper). Conversely, electrical conductivity typically benefits from this treatment and sample builds then show values up to 100% of the IACS standard for pure copper.

Safina is now working on the development of exposure parameters on green laser systems for other manufactured materials including the popular copper alloys CuCr1Zr, bronze and Grcop-42. All of these materials today find their applications in various segments ranging from automotive, energy industry to aerospace.

Download Metal AM magazine