Rosswag supplies AM parts for high-power telescopes

February 7, 2022

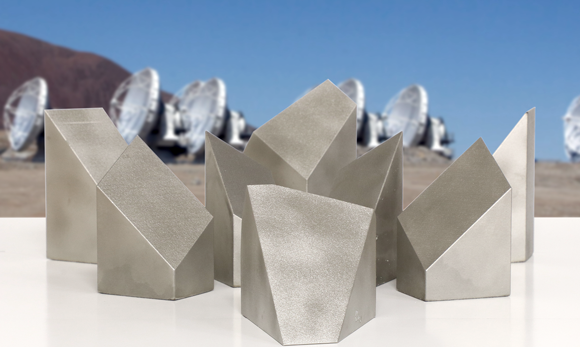

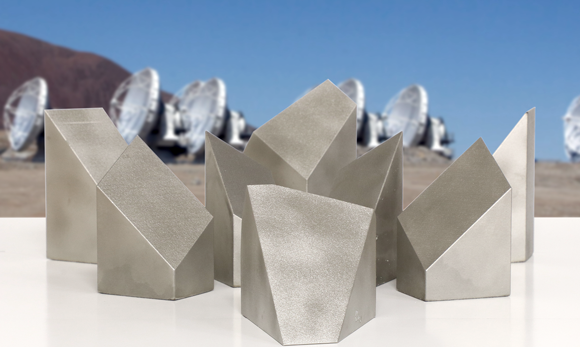

Rosswag Engineering, Pfinztal, Germany, a supplier of metal powders, metal additively manufactured components and qualification services, has produced structural AM parts for six metre mirrors in two telescopes from CPI Vertex Antennentechnik GmbH: the Fred Young Submillimeter Telescope (FYST) and the Simons Observatory Large Aperture Telescope (SOLAT).

The mirrors in these telescopes must maintain a high dimensional accuracy to function correctly, even when under temperature variations. To achieve this, Rosswag selected Invar 36®, an iron-nickel alloy noted for its low thermal expansion and well suited for demanding measuring instruments such as these sensitive and high-precision telescope systems.

“Because we have a high number of variants and a low number of pieces per variant for these Invar 36 components, the [PBF-LB] process is economical and competitive compared to, for example, welding or machining,” stated Michael Solbach, Mechanical Design at CPI Vertex Antennentechnik. “In addition, geometries can also be created that would not be possible with other manufacturing processes, or only at great expense.”

The Fred Young Submillimeter Telescope studies the dynamic interstellar medium in the Milky Way, the Magellanic Clouds and other nearby galaxies. Among other things, it collects measurements to place new constraints on dark energy and the sum of the neutrino masses.

The Simons Observatory Large Aperture Telescope is a crossed Dragone optical design with a six metre diameter aperture to explore CMB science at small angular scale.