Rösler to display Additive Manufacturing post-processing solutions at MACH 2024

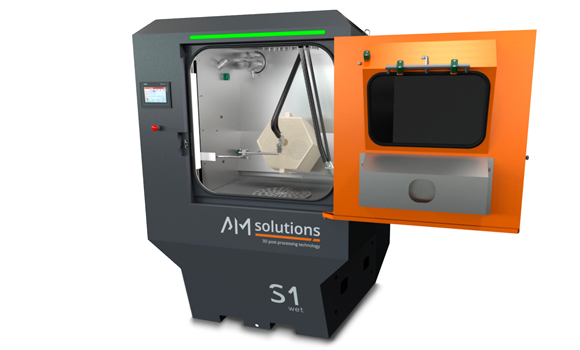

Rösler UK, the UK-based division of Rösler Oberflächentechnik GmbH, based in Prescot, Merseyside, has announced that it will be exhibiting at the MACH 2024 exhibition, a manufacturing industry-focused event taking place April 15-19 in Birmingham, UK. The company will showcase an array of finishing solutions, including two post-processing technologies for Additive Manufacturing: the M1 Basic and the S1 Wet.

The M1 Basic enables the high-quality surface finish of metal or plastic AM parts in a cost-effective and repeatable fashion, and demonstrates how mass finishing technologies is able to eliminate layer lines, burrs, and other surface imperfections on additively manufactured parts. The S1 Wet is a wet-blasting solution for cleaning and finishing surfaces on metal and plastic parts and demonstrates the usefulness of shot blasting technologies for AM parts.

“Rösler has been a prominent player in the mass finishing and shot blasting arena for over eighty years, providing solutions across a range of industry sectors including technologies for exacting medical and aerospace applications,” stated Colin Spellacy, Head of Sales at Rösler UK. “Our impressive track record isn’t just about our longevity, however, it’s a story of accumulating profound knowledge and expertise that only come with time served.

“What sets Rösler apart is its family ownership, which means the company is all about playing the long game, focusing on what really matters: building solid, lasting relationships with clients by truly understanding and evolving with their needs rather than focusing on short term financial gains,” he continued. “This customer-first, quality-obsessed approach has made Rösler a go-to ally for anyone looking for unmatched finishing precision, reliability, and quality. For often complex and demanding applications, Rösler stands as a beacon of trust, proving time and again that when it comes to mass finishing, shot blasting, and bespoke AM solutions, we are here to lead the way and drive innovation.”

Spellacy continued, “We are excited to show attendees at MACH 2024 just what it is that sets our mass finishing and shot blasting technologies apart across all industry sectors. For the UK market, as indeed globally, we offer an extensive sales and service support network offering local expertise and quick responses to customer needs, especially important for applications requiring timely project execution and rapid maintenance responses. Rösler is also truly vertically integrated, manufacturing all machines in-house without third-party components, and this guarantees the highest quality standards — essential in industries where precision is non-negotiable.

“Emphasising automated and turnkey solutions, Rösler caters to the modern demand for efficiency and precision, offering a comprehensive package from design to installation, ensuring minimal error and maximum throughput. As a one-stop-shop for machine and media supplies with a strong post-sale care focus, the company also simplifies procurement, providing ongoing value through maintenance and training, and fosters long-term partnerships, underscoring its commitment to reliable and long-lasting solutions for its customers,” he concluded.

MACH 2024 attendees can find Rösler on stand 6-540.

Download Metal AM magazine