Riven’s new 3D scanning solution makes strides in eliminating manufacturing waste

February 10, 2021

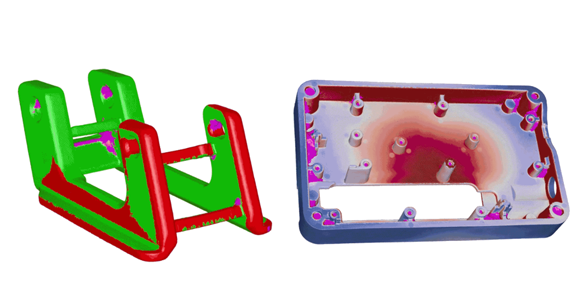

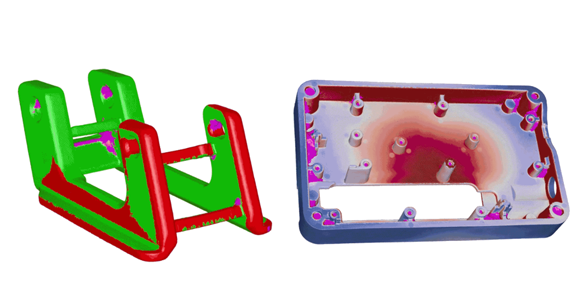

Riven, Berkeley, California, USA, has introduced a push-button 3D scanning, comparison, and communication solution that enables new product introduction (NPI) engineers to quickly scan physical parts, clearly understand detailed physical part deviation from CAD design intent and easily collaborate to resolve issues.

Deviations in first-article or mid-process components during NPI can create problems for manufacturers, applicable to conventional manufacturing, such as Metal Injection Moulding (MIM) or advanced manufacturing, such as Additive Manufacturing. The inability to understand product issues can result in numerous development iterations, shipment delays and cost overruns, leading to unprofitable end products and dissatisfied customers.

“There is an unresolved bottleneck in metal Additive Manufacturing – its NPI – and it fundamentally limits the speed, reach and growth rate of the industry,” stated James Page, CTO. “By accurately measuring complex geometry such as warp, fillet radii and amorphous surfaces, Riven identifies exactly where, and by how much, pre-production parts differ from the CAD design and then uses visual product communication to help teams collaborate on manufacturing and engineering adjustments.”

“Riven is a trusted tool for reducing iterations for MIM sintering operations by quickly providing visual clarity on part deviation,” reported Phil McDonald, Advanced Manufacturing Manager at Alpha Precision Group, headquartered in St. Marys, Pennsylvania, USA. “Problem parts, and there are always problem parts, take the vast majority of my time and Riven is a workflow booster for our team and me.”

According to Page, “Every product iteration takes time, resources and materials. Riven’s cost-effective 3D data capture, analysis, and communication tools provide the missing link for an advancing industry while reducing scrap, travel, and shipping makes important in-roads towards eliminating the $3-trillion of annual manufacturing waste.”

Nate Higgins, president of FreeFORM Technologies, also in St. Marys, added, “Riven is truly easy to use and a game-changer for tuning designs and adjusting parameters faster than ever before. Riven is accelerating metal Additive Manufacturing’s growth surge.”