Riven releases automated re-scaling tool to reduce part warpage

May 19, 2021

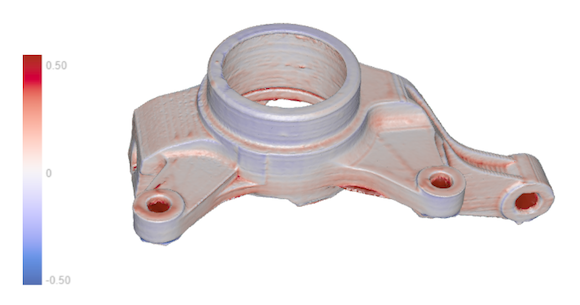

Riven, Berkeley, California, USA, has released a re-scaling tool that automatically computes re-scaling factors as compared to the original CAD, thus allowing for a more accurate end result. Unlike checking dimensions with callipers or a CMM, this method uses full part capture to compute a solution based on the entire part shape. It is suitable for Fused Deposition Modelling, resin-based AM, Powder Bed Fusion, and most metal Additive Manufacturing processes. It can also calibrate entire build volumes for binder jet and other machines.

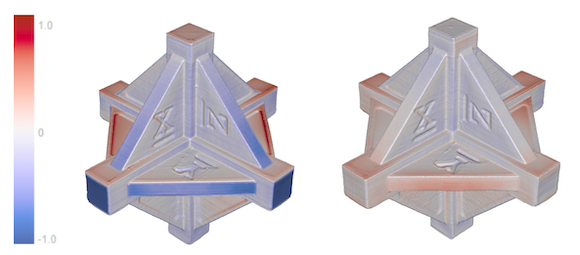

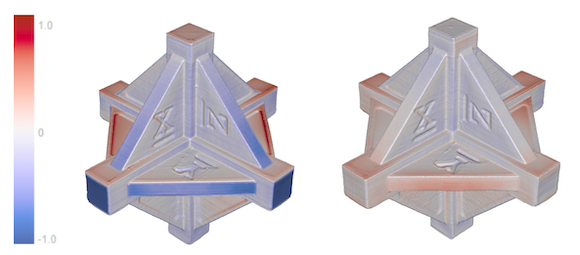

As shown in the top image, a quick re-scaling result on the left for an FDM part clearly shows the problem areas. After applying Riven’s re-scaling factors, the CAD-compare result for the second additively manufactured part (on the right) shows that it is more accurate with deviations reduced significantly in critical areas.

It is reported to take just minutes for Riven’s re-scaling tool to create results with clear indications of the location and degree of variance from the intended design. Once the software has checked a test part, new parts can be adjusted using the established re-scaling factors and manufactured with a reported increase in first-try accuracy.

Further information about the re-scaling software and the company’s other offerings are available via its website.