Rivelin and Solukon partner to advance automated powder removal and finishing

October 3, 2023

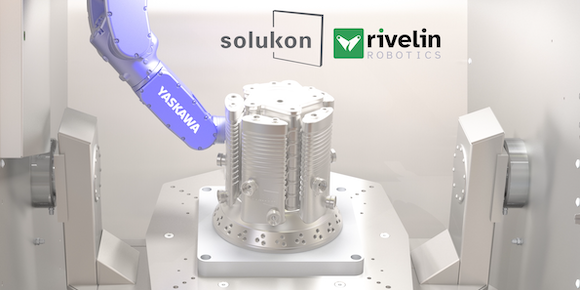

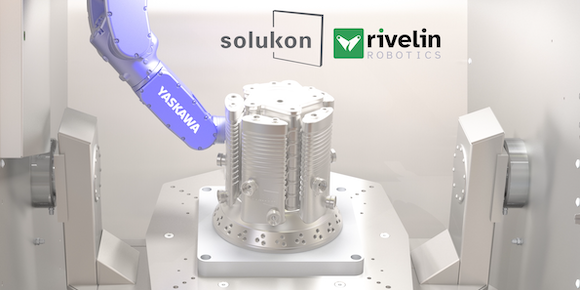

Rivelin Robotics, Sheffield, UK, and Solukon, based in Augsburg, Germany, are partnering to develop autonomous post processing solutions for the metal Additive Manufacturing industry. Together, the companies will integrate Solukon’s powder removal system, the SFM-AT800-S, with Rivelin’s robotic solutions for support removal and finishing, featuring Rivelin Netshape software and Yaskawa EU robots.

Both companies have identified specific challenges cited by customers, specifying the need for robotic compressed air blasting, localised and targeted vibration to assist with depowdering large parts, robotic sensing solutions to inspect air flow in cleared channels, powder blasting and various media blasting for surface enhancement (e.g. glass, grit, sand, nitrogen, etc.).

A working system concept will be introduced on Rivelin’s stand at Formnext 2023, taking place from November 7-10 in Frankfurt, Germany.

“We’re thrilled to hit the ground running at Formnext with our partner, Solukon. This isn’t just another trade show for us; it marks a year since we debuted, and we’ve made some significant strides,” stated Robert Bush, CEO of Rivelin Robotics. “Our Rivelin NetShape Robots have gone from blueprint to reality, and alongside Solukon, we’re crafting automated solutions for post-processing metal AM parts – exactly what the industry’s been calling for. It’s all about delivering real value, and we’re doing it in spades.”

Andreas Hartmann, CEO/CTO at Solukon, added, “One trend that is emerging in Additive Manufacturing is that the internal channels and cavities of parts are getting even more complex. Our aerospace customers in particular have exceptionally high requirements and often work with sticky behaviour materials like copper that require advanced automated depowdering.”

“With programmable rotation, targeted vibration and thanks to our SPR-Pathfinder® software without any human programming efforts, we also get the aerospace parts powder-free with our Solukon technology in a reliable and repeatable way,” he continued. “A very useful task for an integrated robot in our SFM-AT800-S is a channel cleanliness check with blowing or the removal of powder deposits from the surface of the components. We are very glad to have found this experienced partner for automated finishing in Rivelin.”

Download Metal AM magazine