Ricoh 3D collaborates with AMFG to automate Additive Manufacturing workflow

March 27, 2023

Ricoh 3D, the Additive Manufacturing services brand of Ricoh Company Ltd, headquartered in Tokyo, Japan, has deepened its partnership with AMFG, a developer of MES and workflow automation software based in London, UK. AMFG’s automated quotation functionality brings instant ordering capability to Ricoh 3D’s customers and, following over two years of successful partnership, Ricoh 3D has expanded its investment in AMFG’s solution, adopting a number of additional features to leverage the software’s wider capabilities.

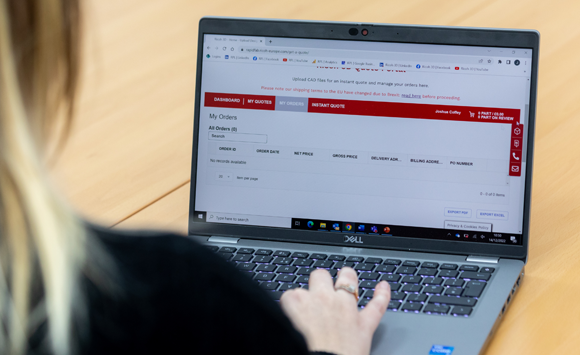

Using AMFG’s instant quotation tool, customers are able to directly upload their files and subsequently receive an accurate quotation in a matter of seconds. Once an order has been confirmed, Ricoh 3D’s projects team are then able to prepare the file for production, making use of the software’s auto-analysis and repair tools.

The upgrade to AMFG’s Ultimate licence includes options such as machine monitoring, build-preparation software preparation, automated production scheduling and integration with shipping providers. Implementing these features is expected to grant critical insights into Ricoh’s medical part production, monitoring operational progress and ensuring that parts maintain consistently exceptional quality levels where needed the most. This provision of full traceability enables the company to conform with exacting ISO:13485 standards, vital for the medical industry.

“When we started the business, we were using manual methods of communicating with customers and transferring parts to people for production,” stated Richard Minifie, a Design Engineer at Ricoh 3D. “AMFG…has totally streamlined that. For example, quoting used to take us over thirty minutes – now it can take us less than two minutes. For us, it’s been a game changer. It’s streamlined our manufacturing process right from start to finish”.

AMFG’s software has been integrated into Ricoh 3D’s business intelligence platform and build preparation software, as well as with its logistics provider. This level of integration is expected to provide Ricoh with a seamless digital thread to manage the full complexity of its Additive Manufacturing operations.

Matt Martin, VP EMEA at AMFG added, “Our journey with Ricoh started a couple of years ago and their transition towards end-parts manufacturing and the complexities of scaling production, are challenges representative of much of the enterprise 3D printing market. Ricoh constantly challenge us with new obstacles in their evolving workflow, and our partnership is driving rapid product development to benefit both them, and the industry as a whole.”

Download Metal AM magazine