Researchers develop anti-fatigue titanium alloy using Additive Manufacturing

March 1, 2024

Researchers from the University of Science and Technology of China have published a study focused on increasing fatigue properties of additively manufactured metals in the journal Nature. As discussed in “High fatigue resistance in a titanium alloy via near-void-free 3D printing,” the team proposed a new strategy to create a titanium alloy via near-void-free Additive Manufacturing techniques.

According to the study, poor fatigue performance of additively manufactured materials under cyclic loading can result from the presence of microvoids.

Under the leadership of Prof Zhang Zhefeng and Prof Zhang Zhenjun from the Institute of Metal Research of the Chinese Academy of Sciences, the research team developed an Additive Manufacturing process route to produce an almost void-free Ti-6Al-4V titanium alloy. This allowed the team to regulate microstructure and defects separately.

This Net-Additive Manufacturing Process (Net-AM) technique includes a Hot Isostatic Pressing (HIP) stage to eliminate the microvoids and subsequent high-temperature-short-time heat treatment to restore the AM microstructure with fine martensite lath. This process has been successful in restoring a nearly void-free Net-AM microstructure to the titanium alloy.

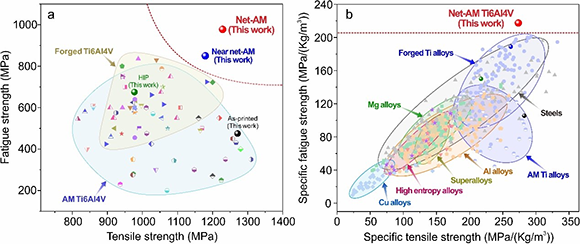

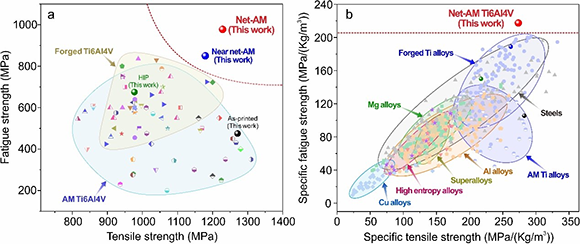

The team confirmed that this void-free additively manufactured alloy has superior fatigue resistance compared to all other additively manufactured and forged titanium alloys, as well as other metallic materials.

“This research has revised people’s previous understanding of the low fatigue performance of 3D printing materials and is expected to advance such materials’ application in aerospace and other fields,” stated Zhang Zhefeng.

To read the full article, click here.

Download Metal AM magazine