Researchers create highly conductive metallic gel for Additive Manufacturing at room temperature

July 19, 2023

Researchers from North Carolina State University, Raleigh, North Carolina, USA; Northwestern Polytechnical University, Xi’an, China; Tianjin University; Xi’an University of Science and Technology; Taiyuan University of Technology; and National University of Singapore have reportedly developed a metallic gel that is highly electrically conductive and can be used to additively manufacture solid metal objects at room temperature.

“3D printing has revolutionised manufacturing, but we’re not aware of previous technologies that allowed you to print 3D metal objects at room temperature in a single step,” stated Michael Dickey, co-corresponding author of a paper on the work and the Camille & Henry Dreyfus Professor of Chemical and Biomolecular Engineering at North Carolina State University. “This opens the door to manufacturing a wide range of electronic components and devices.”

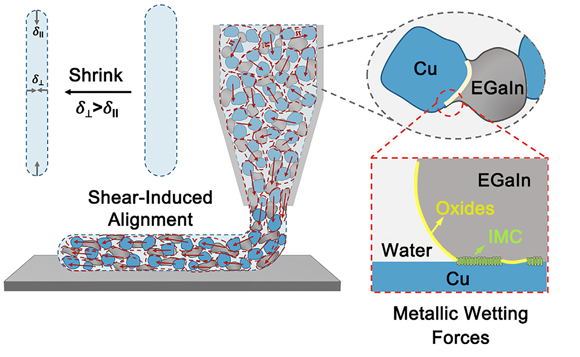

In order to create the metallic gel, the researchers begin with a solution of micron-scale copper particles suspended in water. They then add a small amount of an indium-gallium alloy that is liquid metal at room temperature; the resulting mixture is stirred together.

As the mixture is stirred, the liquid metal and copper particles essentially combine with one another, forming a metallic gel ‘network’ within the aqueous solution.

“This gel-like consistency is important, because it means you have a fairly uniform distribution of copper particles throughout the material,” stated Dickey. “This does two things. First, it means the network of particles connect to form electrical pathways. And second, it means that the copper particles aren’t settling out of solution and clogging the printer.”

The gel can then be used in conjunction with a conventional Additive Manufacturing nozzle, reportedly retaining its shape during manufacturing. When allowed to dry at room temperature, the resulting object is said to become even more solid while retaining its shape. However, applying heat to the printed object while it is drying, has some interesting effects.

The researchers reportedly found that the alignment of the particles influenced how the material dried – for example, if you manufacture a cylindrical object, the sides contract more than the top and bottom when drying.

When drying at room temperature, the process is sufficiently slow and so doesn’t create a structural change in the object, however, when applying heat (for example, placing it under a heat lamp at 80º Celsius), the rapid drying can cause structural deformation. As this deformation is predicable, you can change an object’s shape after it has been manufactured by controlling the pattern of the object and the amount of heat it is exposed to while drying.

“Ultimately, this sort of four-dimensional printing – the traditional three dimensions, plus time – is one more tool that can be used to create structures with the desired dimensions. But what we find most exciting about this material is its conductivity. Because the printed objects end up being as much as 97.5% metal, they are highly conductive. It’s obviously not as conductive as conventional copper wire, but it’s impossible to 3D print copper wire at room temperature. And what we’ve developed is far more conductive than anything else that can be printed. We’re pretty excited about the applications here. We’re open to working with industry partners to explore potential applications, and are always happy to talk with potential collaborators about future directions for research,” Dickey shared.

To view a video of the metallic gel manufacturing and drying process, click here.

The paper ‘Metallic gels for conductive 3D and 4D printing’ has been published in the journal Matter and is available to read here.

Download Metal AM magazine