Researchers at University of Wolverhampton develop improved copper-silver alloys for AM

September 10, 2021

In a project initiated by the increasing demand for heat transfer materials and devices suitable for Additive Manufacturing, researchers at the University of Wolverhampton, West Midlands, UK, have developed additively manufacturable copper-silver alloys that demonstrate superior strength and heat transfer performance in comparison to those that are currently available.

The study was led by the Additive Manufacturing of Functional Materials (AMFM) research group, part of the University of Wolverhampton’s Centre for Engineering Innovation and Research (CEIR).

Highly reflective materials such as silver and copper are known to be challenging for laser beam AM processes. However, establishing the ability to utilise such materials was significant due to the potential enhancements offered by silver and copper alloys in enabling the next generation of aerospace, automotive and biomedical devices.

Silver and copper exhibit exceptional thermal properties in comparison to other metals; silver has the highest thermal conductivity and thermal diffusivity performance properties of any metal, followed closely by copper. The high reflectivity and desired thermal conductive properties, however, create challenges for laser Additive Manufacturing due to laser energy reflection and heat dissipation hindering material meltpool generation.

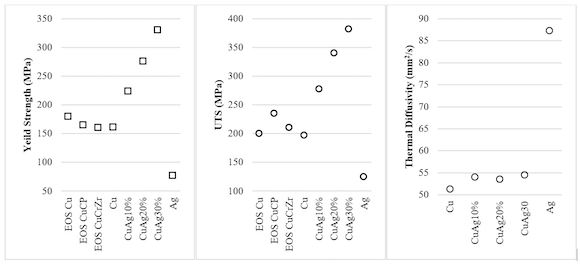

The research at Wolverhampton showed that the copper-silver alloys significantly outperform additively manufactured pure silver, pure copper and all commercially available copper materials evaluated.

The research team – whose expertise comprise AM material and process development – have been investigating combining functional materials with developments in design tools and AM to create high-performance additively manufacturable alloys and devices that show potential for healthcare, automotive, aerospace, and renewable energy applications.

“Thermal management is challenging for many sectors, and even small improvements in heat transfer can have a significant impact on reducing material waste while increasing component reliability and life,” stated Dr Arun Arjunan, Director of the CEIR. “Additionally, emerging systems –such as those in electric vehicles (EVs), radio-frequency systems, high-power light-emitting diodes, solar cells and solid-state laser light sources – all have significant heat dissipation requirements and, therefore, innovative materials and advanced manufacturing technologies are essential to create effective thermal management devices of such systems.”

John Robinson, lead researcher, added, “My previous role as DMLS Development Manager oversaw the metal 3D printing department and associated material and process development activities where we were developing laser processing parameters for gold, platinum and silver alloys. While much of my work was aimed specifically at jewellery and watch applications, I saw significant demand for sterling silver for thermal management applications.”

“While industrial collaborative projects restricted the development of industrial silver-based alloys at that time, the industry demand for enhanced thermal performance materials and complex structures continued after joining the University of Wolverhampton, initiating research in this area,” Robinson continued. “As sterling silver is essentially a copper-silver alloy with 92.5% silver content, it is relatively expensive in comparison to copper and other available 3D printing metal materials. However, for high-value applications such as aerospace and space the enhanced performance may warrant the cost.”

Copper-silver alloys with 30% silver content demonstrated 84%, 100% and 106% higher yield strengths in comparison to commercially available copper, commercially pure copper, and copper-chromium-zirconium, respectively, while ultimate tensile strength was 91%, 62% and 82% higher. Thermal diffusivity was also shown to increase by 6.2% with the addition of silver, demonstrating the potential for the development of high-performance copper-silver alloys for heat transfer and thermal management applications.

Dr Ahmad Baroutaji, study co-author and Mechanical Engineering Course Leader, stated, “This is really the first step for the AMFM research group in custom 3D printed thermally-conductive materials, and research has already begun on 3D printing of materials with exceptional electrical conductivity properties suitable for fabricating induction and electrical windings for electromagnetic applications and electric machines.”

“Furthermore,” he continued, “with the team’s expertise in predictive modelling and crashworthiness complementing our material and manufacturing knowledge, other research projects are already investigating the potential for triply periodic minimal surface (TPMS) structures incorporating thermal management and impact protection for battery in EVs.”

Future planned studies also involve working with collaborators to establish additively manufactured high-purity copper and silver with enhanced IEC electrical conductivity for electromagnetic applications.

All results reported have been peer-reviewed and accepted for publication in Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications.