Renishaw extends ParaMatters collaboration for lightweighting and automation of metal AM

January 14, 2019

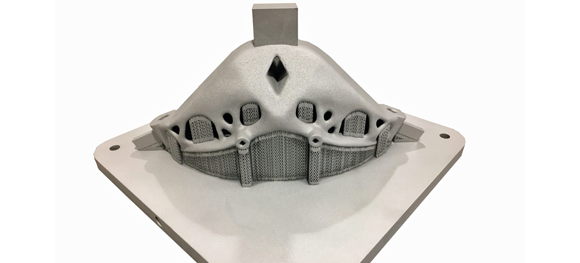

A motorcycle bracket designed using ParaMatters’ CogniCAD topology optimisation software (Courtesy Renishaw)

Renishaw, Wotton-under-Edge, Gloucestershire, UK, has extended its collaboration with ParaMatters, Ventura, California, USA, a developer of autonomous topology optimisation software. Renishaw has previously used the company’s CogniCAD cloud solution to reduce the weight of the upper mounting bracket for ECOSSE Moto Works’ motorcycle, the Nightstalker.

CogniCAD is designed to enable users to easily upload part geometries for optimisation, and is said to automatically produce lightweight macro, meso and lattice structures using generative design principles backed up with high resolution finite element analysis (FEA) validation. Following the extension of the two companies’ collaboration, Renishaw will use CogniCAD at its AM Solutions Center in West Dundee, Chicago, Illinois, USA.

ParaMatters will join Renishaw’s network of software vendors and it is stated the company will provide a ‘Click to Print’ functionality from CogniCAD. This will enable design review and printability assessment by Renishaw experts before manufacturing commences. ParaMatters will also have access to Renishaw AM systems for joint customer projects.

“We worked with Renishaw to establish a smooth workflow that made it possible to automate the entire process from design to manufacturing,” stated Michael Bogomolny, Co-founder & CTO of ParaMatters. “CogniCAD uses topology optimisation, computational geometry and high-performance computing to autonomously generate designs that are adapted to make the best use of AM.”

Working on the Nightstalker, ParaMatters produced a design for the motorcycle bracket which included a lattice structure to reduce the weight of the part. Once redesigned, the bracket’s structural performance was validated using FEA provided by CogniCAD, and assessed by fitting it onto the motorcycle, with the results reported to have exceeded expectations. According to Renishaw, the final bracket was 35% lighter than the original part, the maximum stress was 20% less and the fundamental natural frequency of the part was 2% greater.

“Generative design has a clear role to play in lightweighting parts that cannot be produced by computer numerical control (CNC) machining alone,” explained Stephen Anderson, AM Business Development Manager at Renishaw Inc in Chicago. “However, for many manufacturers, the initial investment required to perform such optimisations is too high. By working with ParaMatters, potential users can easily try topology optimisation, see the results and then engage with Renishaw to assess final suitability for Additive Manufacturing.”

“We successfully use Renishaw to additively manufacture ParaMatters optimised designs and have been really impressed with the results,” added Bogomolny. “We have developed CogniCAD, Meta-Materials Compiler and our new Unique Meso-Structural Designer, that can be used to develop realistic bone-like structural implants – all with simple web-based GUIs allowing for the fast creation of optimal, FEA checked, components. We believe working with Renishaw and implementing ‘Click to Print’ in our offering will help open up ever wider markets for metal additive manufacturing and our software.”