Relativity Space to metal additively manufacture rocket at new HQ

March 5, 2020

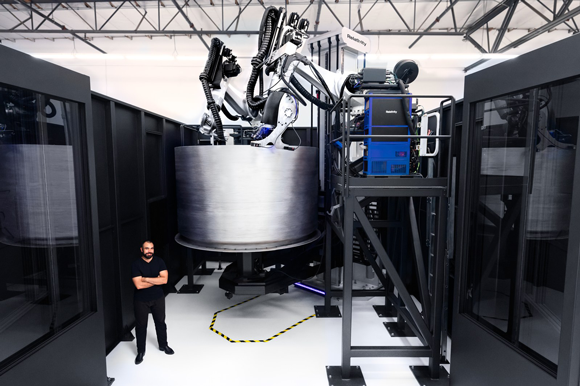

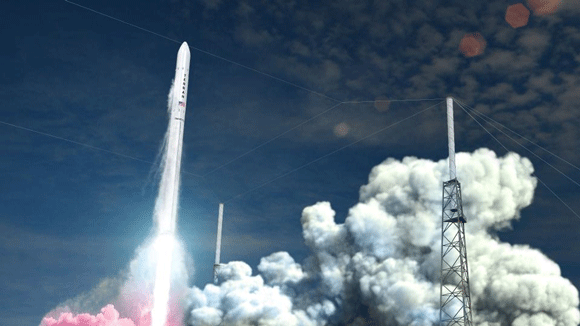

Relativity Space, Los Angeles, California, USA, has secured a new headquarters in Long Beach, California. The 11,150 m2 space will house both the company’s business operations and a manufacturing facility. Relativity integrates machine learning, software and robotics with metal Additive Manufacturing technology and will produce Terran 1, a rocket built entirely using metal AM, at the Long Beach facility.

Relativity has begun migrating staff to its new headquarters, and is transitioning its patented AM system infrastructure, known as ‘Stargate’, as it builds out the autonomous rocket factory. The factory will house all production for Terran 1, the Aeon engine assembly, as well as integrated software, avionics and materials development labs.

The new facility will reportedly enable production of the entire Terran 1 rocket, including an enlarged fairing expected to accommodate double the payload volume. Terran 1 has a 100x lower part count than traditional rockets and can be built from raw material to flight in less than sixty days, using proprietary alloys custom-designed for metal AM to meet mission-critical performance.

“Relativity is disrupting nearly sixty years of prior aerospace technology by building a new manufacturing platform using robotics, 3D printing and AI. With no fixed tooling, Relativity has enabled a massive part count and risk reduction, increased iteration speed and created an entirely new value chain,” stated Tim Ellis, CEO and co-founder of Relativity Space. “I’m confident our autonomous factory will become the future technology stack for the entire aerospace industry.”

The new headquarters and factory mark a milestone in Relativity’s progress towards its first launch. The company recently closed a $140 million funding round led by Bond and Tribe Capital, and has already secured a launch site Right of Entry at Cape Canaveral Launch Complex-16, an exclusive-use Commercial Space Launch Act (CSLA) agreement for NASA test sites, including E4 at the NASA Stennis Space Center, and a twenty-year exclusive use lease for 20,440 m2 factory also at the NASA Stennis Space Center.