Rayvatek and SLM Solutions collaborate to additively manufacture performance aerospace products

July 20, 2023

Rayvatek, a metal Additive Manufacturing technology and service company based in Taiwan, has collaborated with SLM Solutions, Lübeck, Germany, in order to develop high-performance aerospace products and overcome technical constraints associated with traditional manufacturing methods.

Aerospace is a key focus sector for SLM Solutions as its metal Additive Manufacturing technology is said to be ideally suited to producing materials that meet the strict requirements of aircraft engine manufacturers for metallurgical and mechanical performance, enabling efficient manufacturing processes, high product quality, and lower production costs. SLM Solutions’ AM technology can be used to manufacture integral thrust chambers that combine multiple parts into a single part, aiding weight reduction which is crucial in the aerospace sector. Additively manufactured lattice structures and internal cooling channels help to improve part quality, reduce weight, and save fuel. SLM’s technology can be utilised for small batch production of complex parts, enabling cost reductions and tool-free production, significantly shortening the development cycle.

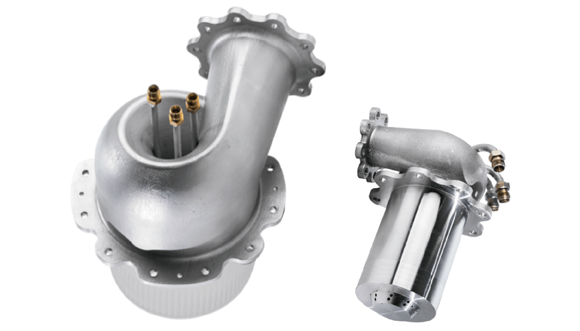

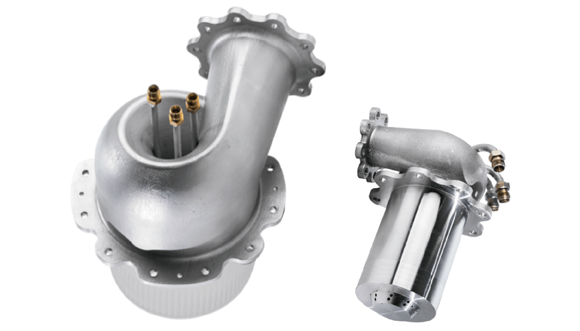

Rayvatek emphasise the value of SLM Solutions’ technology in developing high performance products and overcoming common issues in aerospace materials manufacturing – for example, oxidiser injectors have highly complex internal passages that cannot be produced by casting and machining. These injectors are intricately designed to fit the engine and oxidiser tank, which would require the integration of multiple components if made using traditional manufacturing methods.

Additive Manufacturing technology helps to overcome the constraints associated with traditional manufacturing methods. By using the SLM280 Additive Manufacturing machine, Rayvatec can reportedly manufacture injectors of different sizes through a single manufacturing process, accelerating testing and development time as well as ultimately enabling more efficient injection of oxidiser into the combustion chamber, increasing thrust power for the launch vehicle.

With Additive Manufacturing flow distributors can be printed in one piece, rather than assemble them from several pieces, which helps to achieve the goal of smooth and even distribution. The SLM280 can additively manufacture hollow parts for impellers, reducing the weight and the moment of inertia of the product, thereby improving efficiency, reducing energy consumption.

The SLM280 looks to improve quality control and follow-up testing in the production process for Rayvatek as well as shorten processing time resulting in cost reduction and efficiency increase.

“We are delighted to cooperate with SLM Solutions, a leading metal 3D printing equipment manufacturer. Combining SLM’s high-precision printing capabilities with Rayvatek’s experience and expertise in the space industry allows us to develop and produce high-quality space components and expand our offerings to a wider range of sectors, including aerospace, maritime transport, electric vehicles, motorcycles, bicycles, heavy machinery and moulds, and energy,” shared the CBO of Rayvatek.

Download Metal AM magazine