Protolabs launches digital quoting and design analysis platform for US-based customers

February 12, 2021

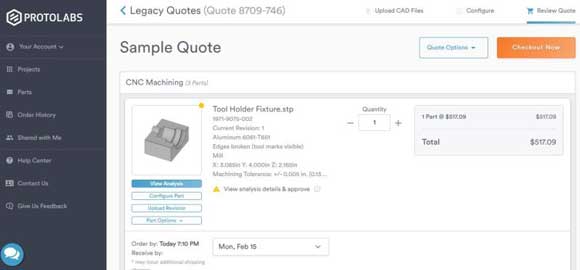

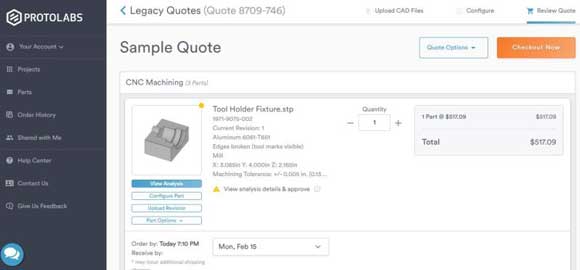

Protolabs, Maple Plain, Minnesota, USA, has launched a new digital quoting and design analysis platform to its US-based customers, following a successful European launch last year.

The company explains that the new platform has a modern, user-friendly interface that enables engineers to better manage their project requirements, collaborate easier with colleagues and identify new levels of transparency into their orders. Like the previous platform, its flagship feature – interactive design for manufacturability (DFM) analysis – remains, but is said to now be more intuitive.

“Protolabs was founded on a digital manufacturing model that would dramatically reduce the time it took to get parts – and it was a success,” stated Rob Bodor, Protolabs’ incoming CEO and current VP and GM of Americas. “Twenty years later we’ve reinvented manufacturing once again with the launch of an all-new digital experience to our customers that reaffirms our position as the global leader in digital manufacturing services.”

Mark Flannery, global product director for e-commerce at Protolabs, commented, “We listened to hundreds of our customers to learn about their design analysis and quoting needs, and then built our new quoting platform around those needs. We then thoroughly tested the platform with our customer base to refine it even further. The result is a digital quoting system designed entirely around an elevated user experience that accelerates their product development cycle every step of the way.”

With the launch Protolabs’ moulding, machining, and Additive Manufacturing services united in a single platform, users are offered easier quoting and ordering experiences. Injection moulding users can now view and discuss gate and ejector pin layout before ordering tooling and parts.

With CNC machining, threading assignments have been simplified to let users quickly assign required threads. AM customers can now see per-part pricing with itemised costs as well as self-select their desired delivery date for each part within order at checkout.

“Unprecedented changes in many of our markets are underway due to customer demand and the ongoing pandemic, but technological advancement in manufacturing are throwing the doors of innovation wide open to allow suppliers and their customers to pivot quickly,” stated Rich Baker, the CTO who led the platform’s launch. “That agility is often the difference between success and failure.”