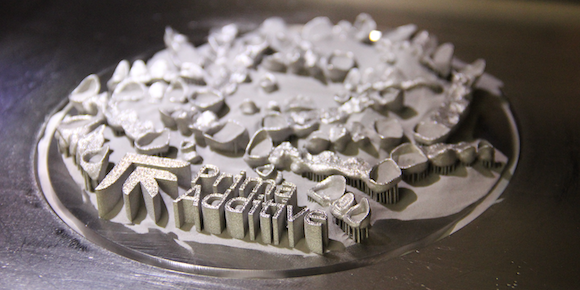

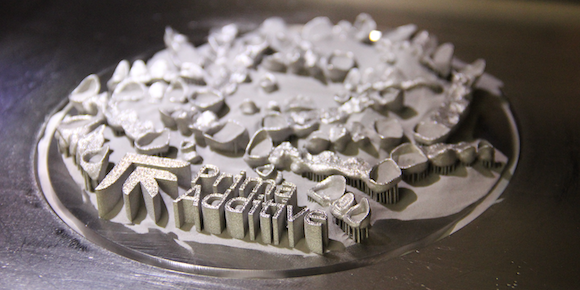

Prima Additive showcases Additive Manufacturing at dental trade show

March 14, 2023

Prima Additive, the Additive Manufacturing division of Prima Industrie Group, headquartered in Turin, Italy, will present a number of additively manufactured solutions at the IDS International Dental Show trade fair in Cologne, Germany, March 14-18.

On the stand, attendees will be able to see the Print Sharp 150 Laser Beam Powder Bed Fusion (PBF-LB) AM machine from Prima Additive. The compact machine consists of a cylindrical working volume of 150 x 160 mm and can produce up to 180 items in a single build job lasting just over three hours. The Print Sharp 150 also features optimised gas flow for minimum nitrogen or argon consumption, and material can be changed in less than two hours due to its modular composition. The machine is equipped with a 300W single mode IR fibre laser source, which is air-cooled, so no external unit cooler is required.

A single line width of 0.1 mm and a minimum layer thickness of 0.02 mm can be achieved, whilst a compact optical scanning system offers high processing speeds and various scanning strategies.

Intelligent control software allows rapid orientation of parts and the defining of machine functions by the operator. With an open process parameter management tool, users can also change key build parameters, select a scanning strategy, and export machine-readable files.

Exhibiting in collaboration with Prima Additive is 8853 S.p.A. which, through its 88dent division, is a customer and partner of Prima Additive in the development of solutions optimised for the needs of dental technicians. 88dent has a Prima Additive Print Genius 150 dual laser machine installed in its laboratory near Milan, Italy, and states that Additive Manufacturing has allowed the company to provide a complete digital workflow, suitable for both small laboratories and large centres of production. Through a dedicated portal available on the company’s website, a customer can upload their prosthesis files and, within 24-48 hours, can receive the semi-finished product.

Download Metal AM magazine