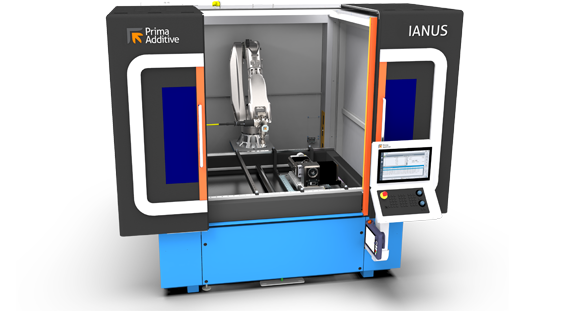

Prima Additive IANUS robotic Additive Manufacturing cell on display at Automatica

June 20, 2023

Prima Additive, a sub-division of Prima Industrie Group dedicated to Additive Manufacturing, headquartered in Turin, Italy, is set to exhibit one of its solutions at the smart automation and robotics trade show Automatica in Munich, Germany, taking place June 27-30, 2023.

Prima Additive is set to display its IANUS Cell at the Siemens booth (Hall B6, booth 302) during the three-day event. Siemens has reportedly proved a crucial partner for Prima Additive as both companies have integrated their technologies in the development of the IANUS Cell, particularly through the integration of the robotic arm and the CNC, through the Sinumerik Run MyRobot/Direct Control functionality. Through this functionality, the user of the machine will be able to operate the robotic cell using a single control console and, above all, they will be able to carry out the movement and programming of the robot using typical instructions of a machine tool, thus exempting them from knowing an additional programming language specific for robots. Additionally, the Siemens systems, on which this platform is based, easily integrate the IANUS Cell with other machines that are already present within the company, taking advantage of digital solutions based on the MindSphere open ecosystem.

The IANUS Cell will be equipped with laser welding at the Siemens booth, one of the four possible processes that can be configured on it. This machine, which boasts a working volume of 1600 x 1200 x 700 mm, is characterised by the possibility of being configured for different laser processes. In addition to laser welding (proximity or remote), it is also possible to configure the machine for Direct Energy Deposition (DED) based on the use of powder or on the use of metal wire as starting material, but also other laser processes such as laser hardening.

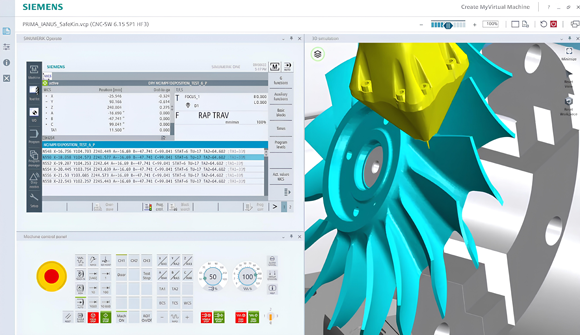

The Prima Additive IANUS robotic cell can be configured to perform two different processes in the same machine. The ability to install two dedicated warehouses makes it possible to switch from one application to another simply by changing the head installed on the robotic arm inside the machine itself. The head change, therefore, becomes comparable to a tool change, increasing the overall flexibility of the system. Thus, it is possible, for example, to equip the system with an infrared laser and a blue laser to be able to use them within the same process in order to work any type of metal alloy more effectively, thus enabling advanced multi-material applications. In order to exploit the full potential of this solution, it is possible to use Create MyVirtual Machine, software made available by Siemens, to generate a digital twin of the system. This has proved to be extremely useful for facilitating the engineering work in the various stages of development and optimisation of the machine, also allowing a considerable reduction in time to market.

Download Metal AM magazine