Phillips selects EOS North America to develop metal AM capabilities

June 23, 2020

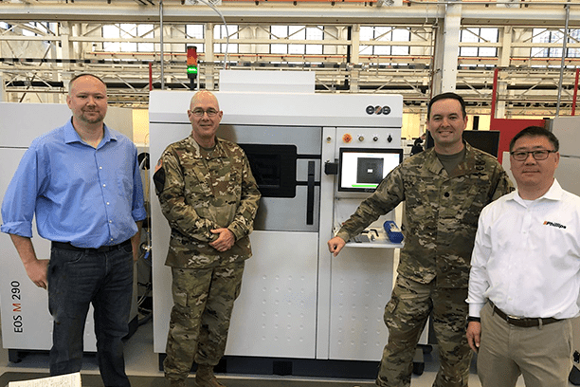

Phillips Corporation’s Federal Division, Hanover, Maryland, USA, has selected EOS North America, the American division of EOS GmbH, as a strategic partner in support of its Public Private Partnership (P3) efforts at the Army Center of Excellence for Advanced Manufacturing (CoE) at Rock Island Arsenal-Joint Manufacturing and Technology Center, Illinois, USA.

As the first Certified Training Partner representing EOS North America’s Additive Minds group, Phillips states that it will deliver advanced engineering and consulting capability, enabling the army to achieve its long-term Additive Manufacturing objectives.

“Deciding to collaborate with a strategic partner to represent EOS in the Federal Government was one of the most important decisions I have ever made in our business,” stated Andy Snow, Senior Vice President at EOS North America.

“The essential elements of a successful partnership consist of a good fit between the partners’ personalities, similar values, the ability to be a team player, compatible goals and clear expectations, and mutual trust. Phillips Federal represents all these values, and we at EOS are delighted to be teaming with them on the Rock Island P3 initiative, as well as many other strategic opportunities across the government sector.”

John Harrison, President of Phillips Corporation Federal Division, commented, “We are grateful to have EOS, the universally recognised world leader in direct metal printing, as a partner at the Army’s Rock Island Arsenal. We look forward to working collaboratively with EOS and achieving the army’s readiness mission through the implementation of Additive Manufacturing.”