Phase3D releases True Layer Thickness in-situ monitoring

March 12, 2024

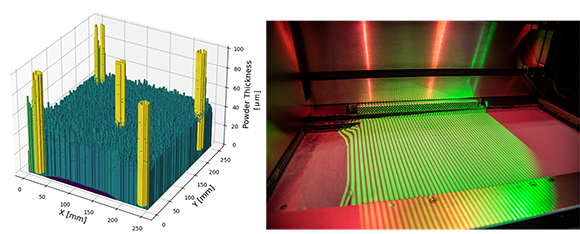

Phase3D, a startup based in Chicago, Illinois, USA, has announced the launch of its True Layer Thickness in-situ monitoring toolkit. True Layer Thickness measures the quantity, in microns, of metal powder spread across the build area of the Powder Bed Fusion (PBF) Additive Manufacturing machine, working to certify uniform distribution for each layer of the build.

Phase3D has worked with a prominent aerospace company to develop the True Layer Thickness toolkit, addressing a critical need to enable high-quality part production. The toolkit is tailored to the challenges of industrial manufacturing, addressing the requirements for industrial applications beyond aerospace, including defence, energy, and medical.

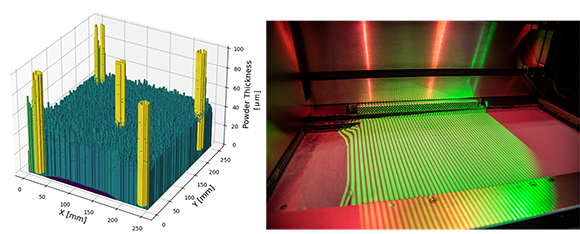

True Layer Thickness uses the company’s patented Fringe in-situ monitoring technology to create quantifiable measurements of the powder spread during the metal PBF process. As it uses the same technology, True Layer Thickness can be seamlessly integrated with Fringe, which, in turn, is suitable for use with most metal Additive Manufacturing machines.

Dr Niall O’Dowd, CEO and Founder of Phase3D, stated, “We are pleased to introduce True Layer Thickness. This new toolkit underscores our commitment to advancing AM for the benefit of widespread adoption of the technology for critical use applications.”

True Layer Thickness is now available for all Phase3D customers. The toolkit can be seen at AMUG 2024, in Chicago, IL at Booth 101 in Salon D.

Download Metal AM magazine