Osseus introduces additively manufactured titanium transforaminal lumbar interbody fusion device

February 8, 2020

Osseus Fusion Systems, Dallas, Texas, USA, a medical device company specialising in advanced technology products for minimally invasive surgery, has launched Aries™-TS, an additively manufactured transforaminal lumbar interbody fusion device.

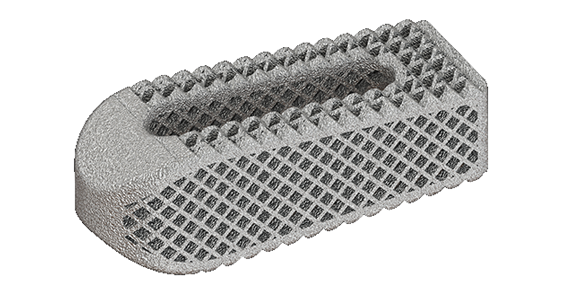

The company explains that its range of Aries devices are constructed from highly porous titanium, which is optimised for bone fusion and biological fixation using Osseus’ Additive Manufacturing technology, PL3XUS. This titanium technology utilises Powder Bed Fusion, specifically Selective Laser Melting (SLM), to create 80% porous implants with increased bone graft packability and lower stiffness compared to competitive devices on the market.

According to Osseus, the Aries family of lumbar interbody fusion devices features a proprietary mesh lattice structure, which helps reduce the stiffness of the cage and maximise bone graft packability. The distinctive mesh structure is optimised to create a superior environment for bone cell fixation and proliferation.

The Aries-TS system is intended for intervertebral body fusion procedures in skeletally mature patients with degenerative disc disease (DDD) of the lumbar spine at one or two contiguous levels from L2 to S1. It also offers aid to Grade 1 spondylolisthesis or retrolisthesis at the involved level(s). The company states that its next interbody to be released will the Aries™-TC Transforaminal Curved Interbody.

“In January, we celebrated the one-year anniversary of the first implantation of the Aries-L lateral lumbar interbody fusion device so we are very excited to follow it up with the launch of the Aries-TS,” stated Robert Pace, CEO of Osseus Fusion Systems. “As a company committed to helping those in need of relief from chronic lumbar pain, we are confident that the Aries™ family of lumbar interbodies is a positive step toward that goal.”