ORNL receives six R&D 100 Research Awards for 2023

August 24, 2023

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL), based in Oak Ridge, Tennessee, USA, have received six 2023 R&D 100 Awards. The winners of the renowned science and innovation competition were announced by R&D World magazine, whose judging panel comprised 45 professionals from across the globe. Entries to the competition were received from fifteen different countries and regions.

“ORNL strives to deliver technological solutions for the nation’s toughest problems,” said interim ORNL Director Jeff Smith. “This year’s R&D 100 Awards are a reminder of how hard our scientists and engineers work to accomplish that feat.”

The winners at ORNL included a number of Additive Manufacturing processes, as well as other technologies. These included the following:

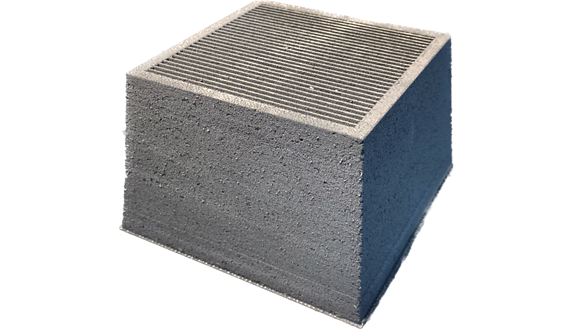

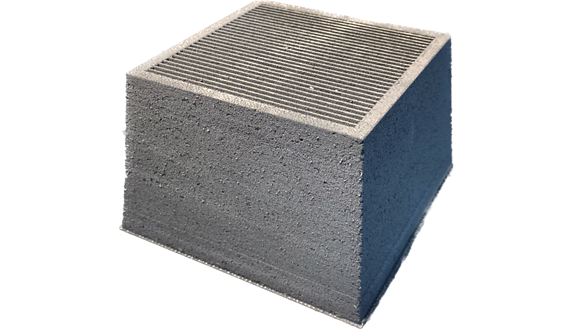

Additively manufactured thermally conductive collimators for neutron instrumentation – ORNL and PolarOnyx

Researchers from ORNL and PolarOnyx, Inc. have developed 2D and 3D collimators and parts using an aluminium-boron carbide matrix composite-based manufacturing process. Collimators are essential components for neutron and x-ray experiments, as they reduce background and ensure that only neutrons and x-rays scattered from a sample are measured. The metal matrix composite (MMC) additive combines the large neutron absorption cross-section and hardness of boron carbide with the high thermal conductivity of aluminium to provide robust neutron scattering measurements with minimal noise.

These complex collimators offer significant improvements over traditionally manufactured collimators. The MMC Additive Manufacturing technique allows for reduced maintenance costs and production times, while also providing unprecedented neutron scattering test performance.

DOE Office of Science provided funding for this research.

Development was co-led by ORNL’s Matthew Stone, Jeff Bunn, Andrew May and PolarOnyx’s Jian Liu and Shuang Bai. Alexander Kolesnikov and Victor Fanelli from ORNL contributed to the development.

OpeN-AM: A platform for operando neutron diffraction measurements of Additive Manufacturing – ORNL

ORNL researchers have developed OpeN-AM, a platform for performing operando neutron diffraction studies of metals during Additive Manufacturing. The platform includes a deposition head, machining capabilities, and infrared monitoring (IR). All of these can be coordinated with operando engineering neutron diffraction measurements using the VULCAN beamline at the Spallation Neutron Source (SNS) at ORNL.

This combination of capabilities provides unparalleled insight into the evolution of phase transformations and stressors that occur during the AM process. These new insights allow for continued improvement of AM processing to mitigate stressors and accelerate development of new materials and process strategies.

Funding for the research was provided by DOE Laboratory Directed Research and Development, Digital Metallurgy Initiative.

Alex Plotkowski from ORNL led development with Chris Fancher, Kyle Saleeby, James Haley, Ke An, Dunji Yu, Tom Feldhausen, Guru Madireddy, Yousub Lee, Joshua Vaughan, Suresh Babu, Jessie Heineman, Clay Leach, Wei Tang and Amit Shyam from ORNL assisting in development.

Physics-informed, active learning–driven autonomous microscopy for science discovery – ORNL

Researchers from ORNL and the University of Tennessee have developed a physics-informed, active learning method for autonomous experiments. This software suite includes active learning algorithms, as well as control software for microscopes and other experimental tools, which expedite scientific discovery.

The advancement of microscopy has transformed the way scientists and researchers study materials and biological systems. However, developing autonomous microscopy poses several challenges, such as automating data acquisition and transfer protocols, developing task-specific machine learning methods, understanding the interplay between physics discovery and machine learning, and defining end-to-end workflows.

This research aims to tackle the current challenges in enabling autonomous microscopy workflows. It does so by striking a balance between the necessary physical intuition, the prior knowledge of scientists and experimental goals with machine learning algorithms that can translate these factors into specific experimental protocols.

Funding for this project was provided by DOE Office of Science.

Co-development was led by ORNL’s Yongtao Liu and Maxim Ziatdinov with Sergei Kalinin from UT Knoxville. ORNL’s Kevin Roccapriore, Rama Vasudevan, Kyle Kelley and Stephen Jesse contributed to development.

Precise, continuous, & high-speed manufacturing of thermoplastic composites using Additive Manufacturing-Compression Molding (AM-CM) – ORNL

Researchers at ORNL have developed a highly automated process for thermoplastic composite manufacturing. This process combines the benefits of Additive Manufacturing and compression moulding (CM) to produce high-performance, functional composite structures at automotive production rates.

The AM-CM process combines the best attributes of conventional processes to produce composite parts. AM deposits reinforced polymers, in which fibres are uniformly dispersed and oriented in the optimal direction, and CM removes voids while imparting a smooth finish.

This process addresses the shortcomings of existing additive and traditional manufacturing processes while incorporating their desirable features. It is said to have the potential to become the dominant manufacturing process for polymers and composites.

DOE’s Office of Energy Efficiency and Renewable Energy, Advanced Materials and Manufacturing Technologies Office (AMMTO) provided funding for this research.

Development was led by ORNL’s Vipin Kumar with ORNL’s Vlastimil Kunc, Ahmed Hassen, David Nuttall, Seokpum Kim, Deepak Kumar Pokkalla, Paritosh Mhatre, Bill Peter, Craig Blue and Joshua Vaughan assisting in development.

SuperNeuro: An accelerated neuromorphic computing simulator – ORNL

To address the current limitations and inefficiencies that hinder large-scale neuromorphic computing, researchers at ORNL have created SuperNeuro. This Python-based open software provides AI practitioners with brain-like simulators that are fast and scalable on central and graphics processing platforms. SuperNeuro uses matrix-based and agent-based modelling approaches, allowing for different workloads and the option of simulating the user’s own spiking mechanisms in a human-interpretable manner.

Compared to existing simulation platforms, SuperNeuro offers an essential neuromorphic software with improved adaptability. It leverages GPU computing to provide superior performance for neuroscience, spiking neural networks (SNNs), and general-purpose computing workloads. Additionally, easy integration with other tools for SNN optimisation opens up possibilities for co-design of neuromorphic circuits. SuperNeuro can be up to 300 times faster than other simulators for small sparse networks and up to 3.4 times faster for large sparse and dense networks.

Funding for this project was provided by DOE Office of Science.

ORNL’s Prasanna Date, Shruti Kulkarni and Chathika Gunaratne co-led the development. Research contributors included, ORNL’s Robert Patton, Mark Coletti and Thomas Potok.

CANDLE (CANcer Distributed Learning Environment)

ORNL also supported the development of CANDLE (CANcer Distributed Learning Environment), which won a 2023 R&D 100 Award in the Software/Services category. CANDLE is a collaboration with multiple DOE laboratories and Federick National Laboratory for Cancer Research for an open-source software platform that provides deep learning methodologies for advancing cancer research.

Download Metal AM magazine