ORNL and NASA additively manufacture lunar rover wheel prototype

October 9, 2023

Researchers at the Department of Energy’s Oak Ridge National Laboratory, in collaboration with NASA, have reported the use of metal Additive Manufacturing to produce a wheel similar to the design used by NASA for its robotic lunar rover. This project aims to demonstrate the technology’s capability to create specialised parts required for space exploration.

The additively manufactured wheel was modelled on the existing lightweight wheels of the Volatiles Investigating Polar Exploration Rover (VIPER), a mobile robot that NASA plans to send to the south pole of the moon in 2024. The purpose of this mission is to map ice and other potential resources and investigate the origin and distribution of water on the moon. It will also explore the feasibility of harvesting enough water from the moon’s surface to support human habitation.

Although the prototype wheel built at DOE’s Manufacturing Demonstration Facility (MDF) at ORNL will not be utilised in the NASA Moon mission, it was constructed to meet the same design specifications as the wheels produced for NASA’s VIPER. Further testing is scheduled to confirm the design and fabrication method before employing this technology for forthcoming lunar or Mars rovers, or exploring its potential for other space applications, such as large structural components.

Additive Manufacturing has the potential to significantly reduce energy consumption, minimise material waste, and shorten lead times. It also allows for intricate design complexity and the customisation of material properties.

Development of large-scale Additive Manufacturing machine

For the construction of the prototype rover wheel, MDF researchers at ORNL used a specialised Additive Manufacturing machine that employed two coordinated lasers and a rotating build plate to selectively melt metal powder into the desired shape. The novel AM machine has the ability to build large objects, being big enough for a person to enter.

Peter Wang, who leads the MDF development of new Laser Beam Powder Bed Fusion (PBF-LB) systems, stated, “We’re only scratching the surface of what the system can do. I really think this is going to be the future of laser powder bed printing, especially at large scale and in mass production.”

Wang and the project team members recently published a study, entitled ‘Improved Productivity with Multilaser Rotary Powder Bed Fusion Additive Manufacturing’, which analyses the scalability of the technology for manufacturing components, such as electric motors.

While the machine itself is unique, the success of the project relied heavily on the researchers’ expertise in process automation and machine control. They utilised software developed at ORNL to divide the wheel design into vertical layers, and then distributed the workload between the two lasers to ensure even construction, resulting in a high production rate. This was made possible by leveraging a computational technique that has recently been submitted for patent protection.

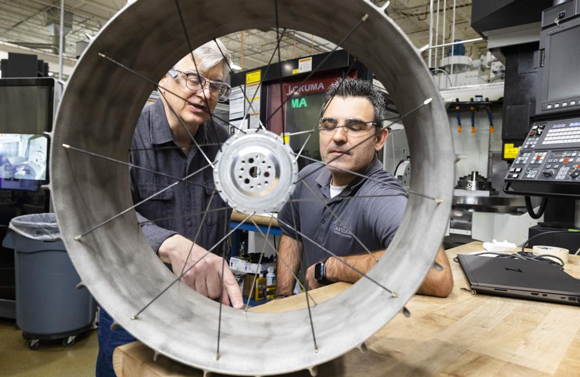

The prototype wheel, which is one of the initial parts manufactured by the new AM machine, showcases the importance of interagency collaboration. “The project with NASA really propelled the technology forward,” shared Brian Gibson, the researcher who led the rover wheel project for ORNL, calling it a milestone. “It was great to connect a capability with a developing need, and the team was excited to be making a prototype component with space exploration applications.”

The prototype wheel, made of a nickel-based alloy, is approximately 20 cm wide and 50 cm in diameter. This size is much larger than typical parts created using metal powder bed systems. The manufacturing process required the ability to produce small geometric features across a large work area. According to Gibson, Additive Manufacturing allowed for a more complex rim design without increasing costs or manufacturing challenges.

In comparison, the four VIPER wheels that will traverse moon dust next year underwent multiple manufacturing processes and assembly steps. The wheel rim, consisting of 50 pieces, is held together with 360 riveted joints. The manufacturing process involved complex and time-intensive machining in order to meet the mission’s rigorous requirements.

If NASA testing confirms that the additively manufactured prototype is as robust as conventionally built wheels, future rovers could potentially use a single additively manufactured wheel rim.

The manufacturing process for this rim took ORNL 40 hours. As part of the project, ORNL and NASA engineers also explored the possibility of incorporating precise design features such as angled sidewalls, a domed shape, and a wavy tread. These features would enhance the wheel’s stiffness, which is challenging to achieve using traditional fabrication methods in the current VIPER wheel design. Additive Manufacturing simplified the wheel design, reduced costs, and made final assembly easier, despite enabling a more complex spoke pattern and spoke locking features.

“A lot of these wheel features were put in just to highlight what you can do with Additive Manufacturing,” added Richard Hagen, a mechanical design engineer for NASA and Additive Manufacturing lab manager at NASA’s Johnson Space Center in Houston. “It lets you easily implement design features that are hard to implement with traditional tooling or even a traditionally machined part.” According to Hagen, ORNL’s capability to construct sizable objects showcases the potential of Additive Manufacturing technology in creating significantly larger wheels for rovers used in lunar and Martian missions.

A challenge is that the specialised AM machine only builds with certain materials. In this case, it uses a nickel-based alloy. As a result, the additively manufactured wheel is 50% heavier than the aluminum VIPER wheel, even though it is manufactured at a similar thickness.

NASA plans to test the performance of the additively manufactured wheel on a rover. This testing will take place either in the rock yard at NASA’s Johnson Space Center or in a simulated lunar environment at a contracted test facility. Evaluators will assess the wheel’s maneuverability, resistance to pivoting, sideways slippage, slope climbing, and other performance metrics.

“Additive Manufacturing offers the flexibility that if you have the feedstock, you could make any replacement part you need, whether in space or on Earth,” Gibson commented. This is one of the reasons why Additive Manufacturing has garnered significant interest for various replacement needs, including rapidly manufactured tooling and hard-to-source castings and forgings. In the context of space exploration and habitation, AM machines could potentially utilise local materials from the moon or Mars as feedstock.

Other researchers from ORNL involved in the project include Jay Reynolds, Gordon Robertson, Greg Larsen, Jamie Stump, Michael Borish, Chris Ledford, Ryan Dehoff, and former ORNL staff member Charles Wade. The project received technical support from Ryan Duncan and Jeremy Malmstead. Funding for the research was provided by NASA and DOE’s Advanced Materials and Manufacturing Technologies Office (AMMTO). The research was conducted at the Manufacturing Demonstration Facility at ORNL, which serves as the home for the MDF Consortium. The consortium is a nationwide group of collaborators working with ORNL to advance state-of-the-art manufacturing technologies in the United States, under the guidance of AMMTO.

Download Metal AM magazine