Optisys additively manufactures largest monolithic metal antenna

August 17, 2020

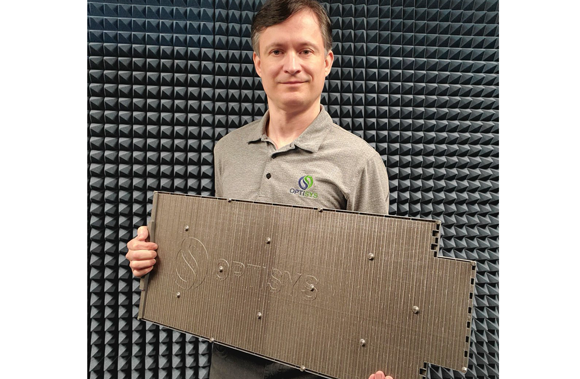

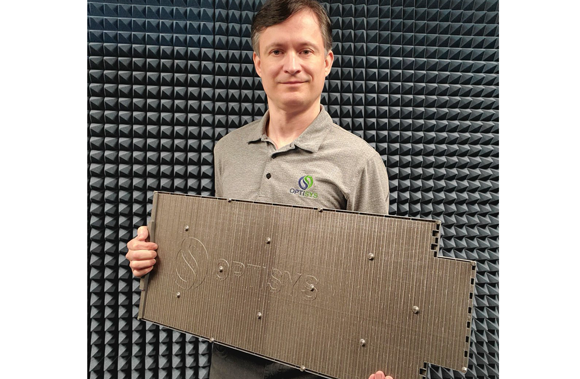

Optisys, LLC, a metal Additive Manufacturing and RF design company headquartered in Salt Lake, Utah, USA, reports that it has completed the development and production of what it states is the world’s largest single build all metal additively manufactured antenna. The large, flat-panel slotted antenna tile is for use in sea, ground, aerospace and satellite applications.

The metal antenna was built as one continuous piece using Laser Powder Bed Fusion (PBF-LB).

“We have been developing ways we can increase the size and cost-efficiency of our large array offerings,” stated Janos Opra, CEO of Optisys. “Today marks the conclusion of an incredible R&D effort to obtain this capability.”

The company explains that the ultra-large tile can form the basis for a much larger array, made up of many of these building blocks, and is suitable for any application already covered by Optisys technology from sea to space. The flat panel slotted antenna was chosen as a development piece because of its reliance on flatness and tight tolerances, attributes which are said to be challenging to achieve on such a large scale using metal AM.

According to Optisys, its successful production of this antenna and the information gained during the process, further extends its capability over legacy technology and competitors.

Michael Hollenbeck, CTO of Optisys, commented, “We have been able to produce any size antenna or radar array, using tiling, for a while now. However, this development brings a new level of cost-effectiveness and we have demonstrated our scalability to truly groundbreaking sizes.”