Open Mind Technologies introduces AM capability for its hyperMILL CAM software

December 16, 2019

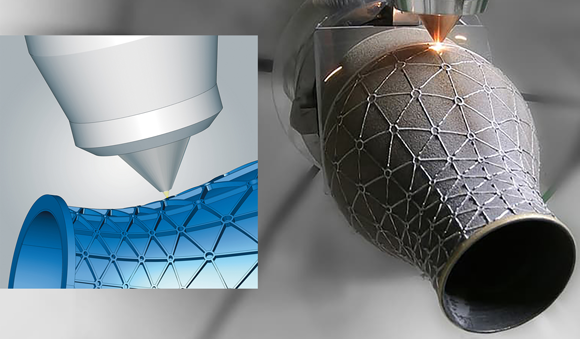

Open Mind Technologies AG, headquartered in Wessling, Germany, a developer of CAD/CAM software solutions worldwide, has introduced an Additive Manufacturing capability into its hyperMILL® CAM software. The introduction of AM capability into hyperMILL is said to enable efficient hybrid processing, with simultaneous additive and subtractive manufacturing on one machine.

For highly complex 5-axis simultaneous processing, hyperMILL Additive Manufacturing reportedly enables an array of flexible options for Directed Energy Deposition (DED) and Wire Arc Additive Manufacturing (WAAM) processes. Both laser-based powder nozzle machining heads and WAAM energy sources can be controlled using hyperMILL AM for selective material deposition, and can be programmed and automatically simulated for collision avoidance.

Alan Levine, Managing Director of Open Mind Technologies USA, Inc., stated, “As an early adopter of driving forward the implementation of integrated process chains, Open Mind has optimised hyperMILL Additive Manufacturing technology to boost the efficiency, precision and process reliability of additive and hybrid manufacturing.”

Key applications for hyperMILL Additive Manufacturing include the repair of damaged components, cladding of additional surface skins, or creation of new components from a substrate. This is also expected to create new options for AM combining different materials, such as the addition of high-quality material layers to carrier materials.