Open Additive awarded contract to develop multi-laser AM technology

June 2, 2020

Open Additive, LLC, headquartered in Beavercreek, Ohio, USA, has been awarded a $2.94 million, twenty seven-month Air Force Commercial Readiness Program (CRP) contract to advance its metal Additive Manufacturing technology and product line to industrial scale.

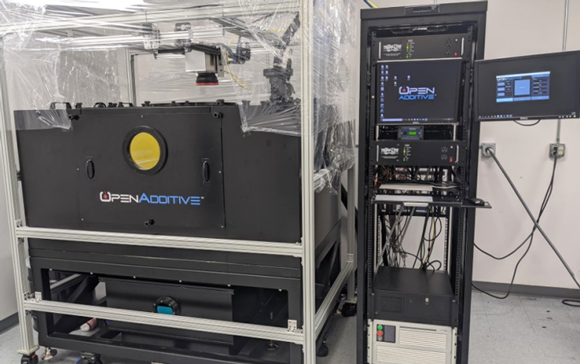

The ‘Open Systems Platform for Multi-Laser Additive Manufacturing’ contract reportedly builds on the company’s prior Small Business Innovative Research (SBIR) portfolio and independent research to develop open-architecture Laser Beam Powder Bed Fusion (LB-PBF) systems with advanced processing and in-situ monitoring capabilities.

Open Additive states that the CRP aims to accelerate the transition of SBIR/STTR technologies, products and services to Phase III and into the defence acquisition process. The new CRP contract (FA8650-20-C-5007) is sponsored by the Air Force Research Laboratory (AFRL), Materials and Manufacturing Directorate, Wright-Patterson Air Force Base, Ohio. The University of Dayton Research Institute (UDRI) serves as the primary project partner.

According to the company, the programme seeks to develop and demonstrate a prototype quad-laser LB-PBF platform with full user control of standard and advanced processing parameters, multi-sensor monitoring and feedback control, and integrated heated build plate with 600 mm x 600 mm build area, all configured within a versatile form factor.

The contract was awarded in February of this year, completing its first technical review this April. Dr Thomas Spears, Open Additive’s Chief Scientist, serves as the project’s Principal Investigator, having joined the team in September 2019 after spending six years at GE Aviation and GE Additive, where he led technology and product development in metal AM.

“This effort paves the way to extend the versatility and advanced capabilities of our smaller systems to a much larger and more capable platform for the defence industrial base,” commented Dr Ty Pollak, President of Open Additive, LLC. “We’re excited to support the Air Force push in this direction.”