Oerlikon and RUAG collaborate on production of metal additively manufactured space components

July 19, 2018

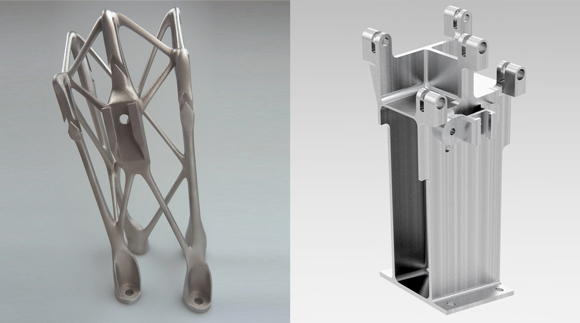

Additively manufactured metal bracket for space applications (left) and the original version (right) (Courtesy RUAG Space)

Oerlikon, Pfäffikon, Switzerland, signed a Memorandum of Understanding (MoU) with RUAG Space, Zurich, Switzerland, a division of Group RUAG, during the Farnborough International Airshow, UK, July 16-22, 2018, to qualify and accelerate the series production of metal additively manufactured space components.

Oerlikon and RUAG Space are currently working together on the qualification of a bracket for installation on a payload fairing. A new optimised design for Additive Manufacturing will reportedly reduce the part cost by 25% and decrease part weight by more than 50%, while doubling the stiffness of the bracket.

Dr Roland Fischer, CEO, Oerlikon Group, stated, “Through our ongoing collaboration with RUAG Space, we have identified opportunities to fine-tune the qualification and certification processes, which are crucial in ensuring consistent quality in production. We are confident, that our materials and Additive Manufacturing expertise will further grow this important partnership.”

Within the partnership, both companies stated that they intend to co-develop processes and standards for the metal AM of space components, with the intention being to establish standards suitable for the European space community to adopt. In addition, the partnership will explore the refinement of existing alloys for the Additive Manufacturing process and the development of new metallic materials to unlock future design opportunities.

“We see this partnership as an important step in unleashing the full value of Additive Manufacturing in the development of new products that meet the rapidly evolving demands of the space industry,” commented Peter Guggenbach, CEO, RUAG Space. “We are working on standardising AM operations for space and are excited to collaborate with Oerlikon AM to further develop industry-leading standards and processes.”