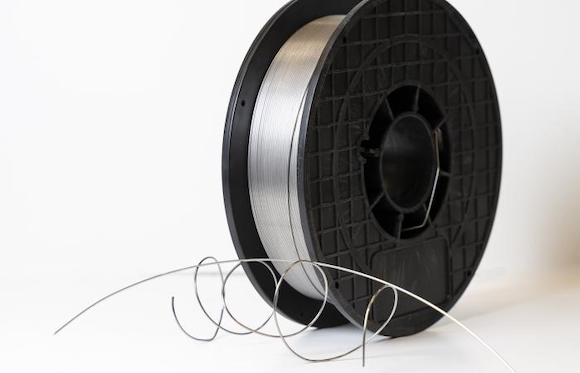

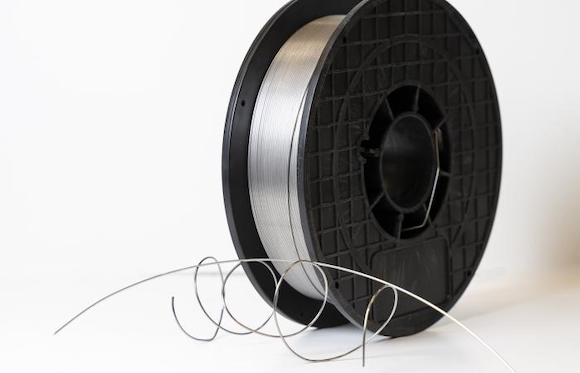

Novel weld wire could avoid distortion and increase strength in additively manufactured steel parts

February 9, 2023

The US Departments of Energy’s Oak Ridge National Laboratory (ORNL), Tennessee, and the US Army’s Ground Vehicle System Center (GVSC), Warren, Michigan, have partnered to develop a series of weld wire materials targeted at high-strength steel repair in vehicles, bridges and pipelines. The team believe this novel wire may also prove useful in Additive Manufacturing, where it can be used to avoid distortion and increase strength in steel parts.

The new wire is said to enable onsite welding without costly heat treatments typically used to reduce residual stresses and material distortion. It solves a major problem of welded steels that occurs when hydrogen atoms enter the metal during welding and reduce the metal’s ductility, toughness and strength. Subsequently, high tensile residual stress leads to cracking.

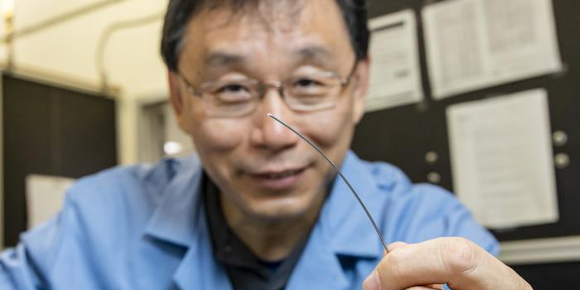

“The filler material that ORNL and the US Army invented is a unique and game-changing solution for residual stress control, distortion reduction and avoidance of hydrogen-induced cracking for a wide range of structural steels,” stated Zhili Feng, who leads ORNL’s Materials Joining Group. “Huge economic benefits could come from eliminating cracking and post-fabrication distortion in welded or 3D-printed steel structures.”

Stan David, an ORNL corporate fellow emeritus who led the lab’s welding program for 25 years before retiring, added “About 80% of welded structures in the United States are made of steels, so applications for our innovative fill metal are extensive. It is cheaper to repair a structure than to replace it. Our filler provides high-quality weld joints for increased service life of welded structures in demanding environments. The invention could potentially save US industry hundreds of millions to billions of dollars each year.”

If stronger steel is used to make a welded structure, however, then less of it is needed, thus reducing weight, saving energy and cutting carbon dioxide emissions during materials manufacturing and vehicle operation. That results in more fuel-efficient cars, lighter-weight combat and support vehicles, and more durable fuel pipelines. However, strong steels are especially prone to hydrogen-induced cracking.

To overcome this challenge, the scientists at ORNL and GVSC partnered to invent an alloy with a unique chemical composition that can join strong steels while reducing residual stresses. The alloy’s ability to resist hydrogen-induced cracking comes from a novel phase transformation in the weld. As a weld cools, the filler material combats tensile stress – or ‘bad stress’ – which pulls at steel’s crystalline microstructure to lengthen and break it. The phase transformation introduces compressive stress – ‘good stress’ – to compensate for bad stresses as the weld cools.

The weld wire’s chemical composition was initially developed to repair cars and evolved to fix tanks, since progressing to mend pipelines and other critical infrastructures. The DOE Hydrogen Program, led by EERE’s Hydrogen and Fuel Cell Technologies Office, conducts R&D in areas including hydrogen delivery, infrastructure and storage. In 2016, the programme ramped up efforts addressing challenges to pipelines transporting gaseous hydrogen both alone and mixed with natural gas. It also explored challenges to high-pressure vessels for storing liquid hydrogen.

Feng’s team worked to further refine the wire for pipeline steels, which have different chemical compositions and strengths compared to steels for cars and military tanks. In 2019, DOE’s Fossil Energy and Carbon Management Office began looking into extending the lives of millions of miles of ageing oil & gas pipelines with this newest weld wire through various repairs that minimise hydrogen-induced cracking and avoid expensive and time-consuming preheating and post-weld heat treatment.

The researchers have applied for a patent of their novel weld wire.

Download Metal AM magazine