NMIS’ £1 million project encourages Scottish SMEs to explore Additive Manufacturing

February 6, 2024

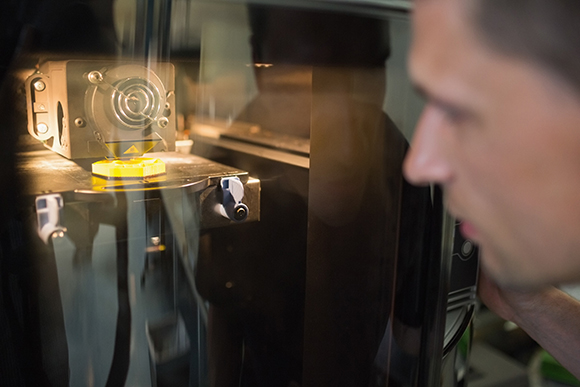

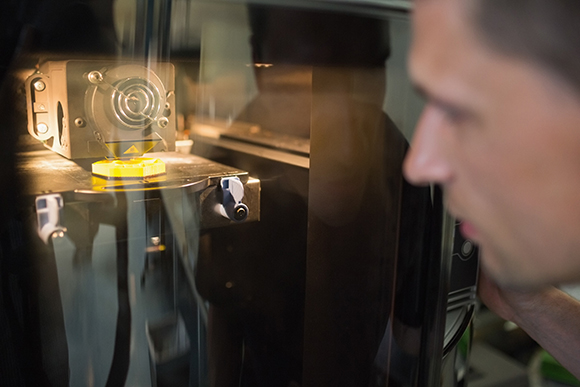

The National Manufacturing Institute Scotland (NMIS) has completed a £1 million project that has encouraged over 100 small to medium-sized enterprises (SMEs) across Scotland’s manufacturing industry to explore the potential of Additive Manufacturing.

The three-year Additive Manufacturing Business and Technology Support (AM-BATS) project has helped small businesses across various sectors learn more about designing and adopting new processes, with the end goal of developing more sustainable products and entering new markets. The programme was operated by the University of Strathclyde and part of the High Value Manufacturing Catapult (HVMC) and was funded through the Scottish Government’s Advancing Manufacturing Challenge Fund via the European Regional Development Fund.

The thirty-six projects took place involving different manufacturing businesses, including renewable energy and electric vehicles, food and drink, sports, oil and gas, and medicine. NMIS assisted companies with a range of activities, such as exploring the initial feasibility of Additive Manufacturing for a particular scenario, providing knowledge and skills, designing systems, setting up factory equipment, and assessing sustainability benefits.

Some businesses began from scratch, seeking to understand what AM is and what it can offer, while others sought help to accelerate and develop existing processes they already had experience with. Many of the businesses have since created new products or changed existing ones to include additively manufactured elements. Several have now adopted AM due to its benefits, including reduced development times, increased sustainability, design optimisation, faster time to market, and the ability to utilise digital inventories.

Among them, medical equipment manufacturer Confidence Plus received support from the NMIS team to develop a new product designed to support people using ileostomy bags. Using AM, several prototypes were created for the new glider device from recycled materials, and these are now being trialled by ileostomy bag users.

Anne Inch, founder and managing director at Confidence Plus, shared, “Working with NMIS on our medical device will enable us to access new markets and could see the creation of new job opportunities in the healthcare manufacturing industry. The device aims to make a big difference to the lives of users of ileostomy bags and we were grateful for the team’s support in exploring this new innovative technology. We couldn’t be happier with the outcome.”

As a direct result of the support received, another business, FluidMS, a technology company that creates devices for 24/7 health exposure monitoring in manufacturing facilities, saw product assembly times reduced from sixty minutes to ten minutes per unit. FluisMS has also adopted AM internally and introduced design and manufacturing capabilities for the first time.

Using Additive Manufacturing, Stonehaven-based Whittaker Engineering also saw lead times shortened from several months to just nine days for its components used in the oil and gas sector.

Two training courses were developed through the project, offering companies and engineers an introduction to Additive Manufacturing via NMIS’ Manufacturing Skills Academy.

Download Metal AM magazine