Nikon SLM Solutions and Materialise to interlink software with machines

November 9, 2023

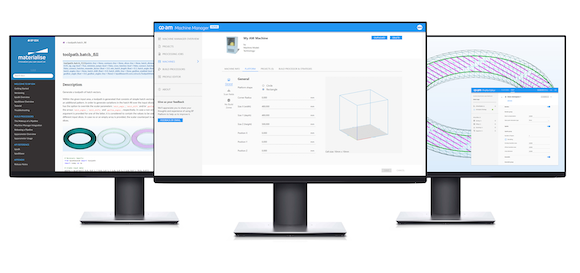

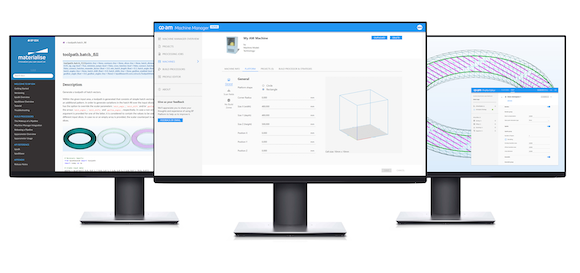

Nikon SLM Solutions, based in Lübeck, Germany, and Materialise NV, headquartered in Leuven, Belgium, have announced a collaborative venture to tailor the next generation of Materialise build processors (BP) for use with Nikon SLM Solutions’ Additive Manufacturing machines, integrating them into the Materialise CO-AM platform.

With its NXG machines, Nikon SLM Solutions is positioned as a provider of highly productive metal AM machines designed for high-volume manufacturing. Powered by twelve 1 kW lasers, these machines feature a large build envelope facilitating substantial part sizes and quantities in a single run.

However, the expansive build volume necessitates the processing of a substantial data volume, which traditionally elongates calculation times, thus impeding the workflow to initiate build jobs. Bridging the gap between data preparation and actual Additive Manufacturing is vital to harnessing the technology’s full productivity.

Nikon SLM Solutions and Materialise have amalgamated expertise to curate the next-gen BPs, addressing this bottleneck and providing AM users the space to modify their AM process as per their requisites. The novel BP is slated for release in the upcoming months for NXG and all SLM users employing Materialise software solutions.

“Working with Materialise, we have made a giant leap in developing a high-performative build processor,” stated Nicolas Lemaire, Product Manager – Software, Product Control, and Strategic Partnerships at Nikon SLM Solutions. “With this next generation of build processors, our customers using Materialise software will save time during the print job setup and profit from tools to optimise their print process.”

A BP acts as a conduit, linking AM machines with data preparation software like Materialise Magics. Post-data preparation, an extensive data volume requires processing to furnish the requisite information for the AM machine to fabricate the parts. The forthcoming Materialise BPs expedite this phase, offering AM users the flexibility to customise process parameters to optimise application outcomes.

This milestone was reportedly achieved through the Materialise BP Software Development Kit (SDK), fostering close collaboration during development and allowing machine manufacturers to securely encapsulate their own intellectual property. By fine-tuning print parameters, it is stated that users can attain the sweet spot of cost-efficiency, production speed, and part quality, enabling the manufacture of intricate parts and mass production of identical or personalised products with consistent quality, reduced scrap rates, and abbreviated lead times.

Bart Van der Schueren, CTO of Materialise, added, “Nikon SLM Solutions and Materialise share a vision of open systems that enable AM users to make optimal use of their equipment and connect it to their preferred solutions. We look forward to offering the next generation of BPs to Nikon SLM Solutions users and providing them access to software solutions covering the whole AM workflow.”

Discover more at Formnext, visit Nikon SLM Solutions in Hall 12.0, D119 and Materialise in Hall 12.1, C139.

Download Metal AM magazine