New low cost system offers easy access to metal Additive Manufacturing

November 7, 2016

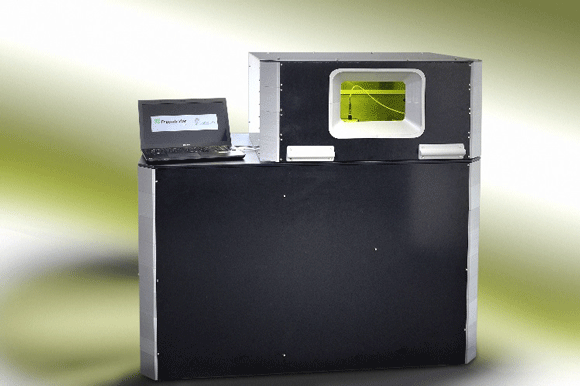

The SLM unit for Additive Manufacturing of stainless steel components is particularly suitable for entry-level users (© Photo Fraunhofer ILT, Aachen, Germany)

Germany’s FH Aachen and Fraunhofer Institute for Laser Technology ILT have announced the development of a new low-cost Selective Laser Melting (SLM) unit that will be displayed at this year’s formnext, Frankfurt, Germany, November 15-18, 2016. Built jointly with the GoetheLab at FH Aachen, the unit is intended primarily for small and medium-sized enterprises and will cost around €30,000.

Employing a Cartesian coordinate system, the first functional prototype of the new system uses a 140 W laser diode with a focus diameter of 250 µm to produce complex metal components with a maximum height of 90 mm and a maximum diameter of 80 mm. The machine’s footprint measures 1.3 m x 0.8 m x 1.4 m.

According to Dawid Ziebura, Project Engineer at Fraunhofer ILT a unit with a comparable installation space would cost at least €100,000, whereas the FH Aachen/Fraunhofer ILT SLM unit will retail for €30,000. The unit is said to be easy to use, with entry-level users only requiring a few hours to learn how to operate it. All of the components in the sytem allow users to maintain the unit themselves and are easy to replace. “The low-cost unit makes it easy for entry-level users getting into 3D printing of metal components,” Ziebura added.

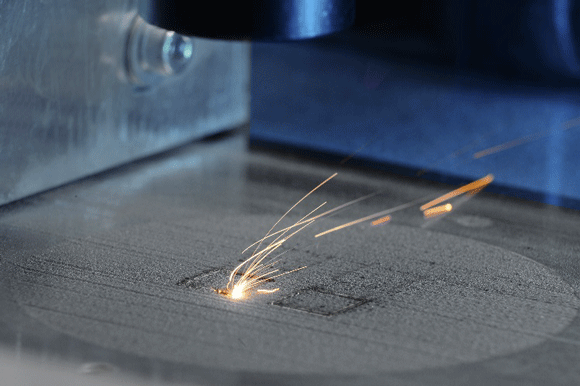

The exposure process in action (© Fraunhofer ILT, Aachen, Germany)

The components that the unit can produce are suitable for many typical SLM applications, ranging from prototypes and sample parts to functional components. Users can select the speed and the production quality at which the unit operates. It was stated that the system can produce a medium-sized (55 cm³), stainless steel part at a density of more than 99.5% within 12 hours.

In addition, the unit offers the option of producing lattice structures for large-volume areas in order to shorten the construction time of less stressed areas. Selecting a lattice density of 20% (corresponding to 20% of the original volume) reduces construction time by 60%.

The engineers in Aachen now want to shorten process times and optimise exposure strategies in order to improve component quality. They are also planning to manufacture components made of aluminium alloys and tool steel.

The new low-cost SLM unit can be seen in action at the Fraunhofer booth at formnext: Hall 3.1, Booth E60.