National Physical Laboratory adds Indentation Plastometer for mechanical testing of metal AM parts

August 29, 2023

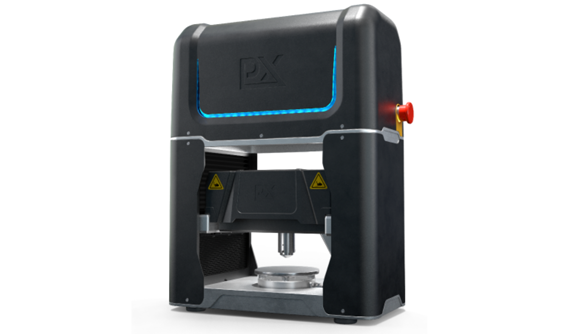

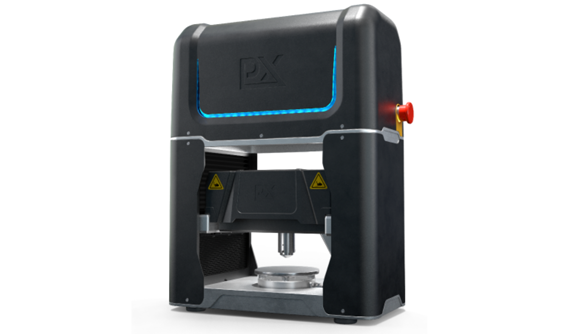

The National Physical Laboratory (NPL), a public sector research establishment which serves as the UK’s National Metrology Institute, has added an Indentation Plastometer from Plastometrex for the mechanical testing of metallic materials, including those produced by Additive Manufacturing. Initially, NPL will use the system to test the strength of complex lattice structures and small parameter cube samples made by Laser Beam Powder Bed Fusion (PBF-LB).

The Plastometer is powered by advanced algorithms that allow it to extract metal stress-strain curves from a five-minute indentation-based test. The process is reported to be ideally suited to Additive Manufacturing due to its unique ability to test small and complex shapes quickly and affordably. This provides users with the necessary data to make confident and informed engineering decisions.

Tony Fry, Principal Scientist at NPL, shared, “The Indentation Plastometer allows us to characterise the properties of finely structured parts in an entirely new way. The data allows us to build up a more comprehensive picture of the properties of parts made via Additive Manufacturing, deepening our understanding of the process.”

Plastometrex and NPL are working on several projects. These include supporting the standardisation of the technology, utilising the tool in the AM market, and the development of Plastometrex’s upcoming high-temperature system, HotPIP.

Professor Bill Clyne, Chief Scientific Officer at Plastometrex, added, “We are delighted to be working with NPL, a world-leading organisation in this field. We are looking forward to collaborating with them on several projects that push the frontier of measurement technology for the benefit of the economy and the environment.”

Download Metal AM magazine