NASA’s GRX-810 alloy undergoes successful hot-fire testing for liquid rocket engines

January 19, 2024

NASA first reported the development of its GRX-810 powder in 2022, an oxide dispersion strengthened (ODS) alloy specifically for use in extreme temperatures. This Ni-Co-Cr based alloy was designed for aerospace applications, including liquid rocket engine injectors, preburners, turbines, and hot-section components, where it is required to withstand temperatures up to 1100°C.

The alloy was created using integrated computational materials engineering techniques to focus on a new class of materials that provide exceptional temperature and oxidation-resistant properties. GRX-810’s aim is to bridge the temperature gap between traditional nickel-base superalloys and refractory alloys.

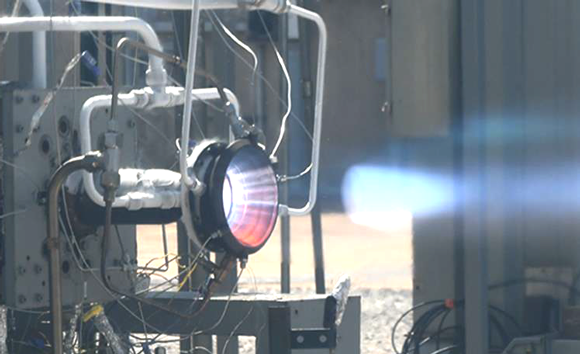

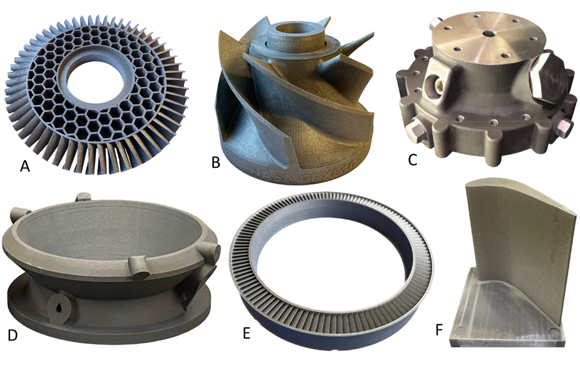

The GRX-810 alloy utilises Additive Manufacturing to incorporate nano-scale yttria particles throughout its microstructure and, compared to traditional nickel-base superalloys, is said to provide a two-fold increase in tensile strength, 1,000-fold better creep properties, and two-fold improvement in oxidation resistance.

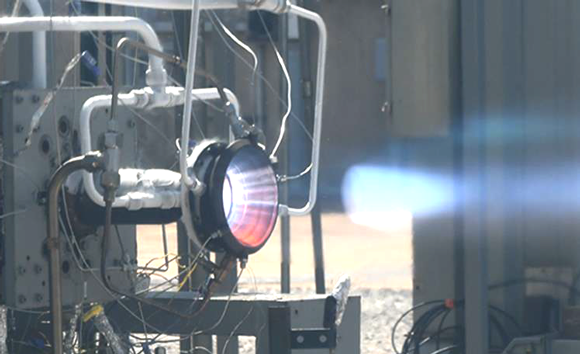

As discussed in a paper presented at the 2024 AIAA Science and Technology Forum and Exposition (AIAA SciTech Forum), January 8-12, 2024, Orlando, Florida, USA, a team of NASA researchers led by Paul R. Gradl, Combustion Devices Manufacturing and Design Engineer at NASA’s Marshall Space Flight Center in Huntsville, USA, confirmed a successful series of hot-fire tests using liquid oxygen/liquid hydrogen (LOX/LH2) and liquid oxygen/liquid methane (LOX/LCH4) propellants. Rigorous high-duty cycle testing of various injectors and nozzles was reported to have demonstrated improved life compared to traditional nickel-base superalloys.

The authors explained that a coating process for the powder feedstock was refined to enhance the high-temperature properties of GRX-810. This involved coating pre-alloyed base powder with <1 wt.% Y2O3 nanoparticles, ensuring even dispersion when additively manufactured using Laser Beam Powder Bed Fusion (PBF-LB).

The ODS coating, achieved through AM, was said to address the historical cost challenges associated with traditional ODS alloy production and resulted in a well-distributed and stabilised microstructure at elevated temperatures. It was stated that a single heat treatment using Hot Isostatic Pressing (HIP) minimises grain growth, further enhancing the material’s structural integrity.

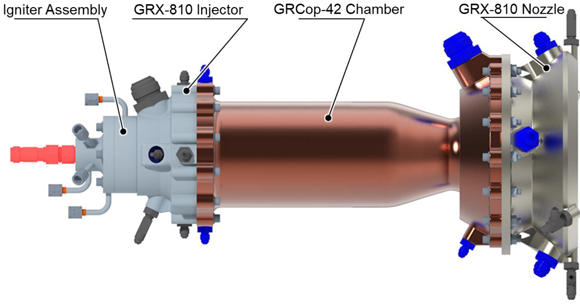

The GRX-810 components used in the hot-fire test were additively manufactured on an EOS M280 using atomised feedstock from Praxair. Testing was conducted at NASA MSFC test stand 115 under the Optimised and Repeatable Components using Additive (ORCA) development project and Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) collaboration. The RAMFIRE test series incorporated the GRX-810 injector shown in Fig. 2, whereas the ORCA test series used both a GRX-810 injector and nozzle (Fig. 3).

Liquid oxygen/liquid hydrogen and liquid oxygen/liquid methane versions of GRX-810 pentad injectors using a centre-mounted torch igniter were built. Two truncated ideal contour GRX-810 nozzles were fabricated as well. The injectors accumulated 3,117 seconds of hot fire across pressures of 37.4 to 57.2 bar, and the nozzles accumulated over 2,458 combined seconds.

The authors concluded that the successful application of GRX-810 alloy in hot-fire testing, particularly in LOX/LH2 and LOX/LCH4 environments, demonstrated its robustness and readiness for aerospace applications.

Future work involves additional scaling and analysis of the GRX-810 alloy feedstock and both PBF-LB and laser powder-based DED builds for large-scale production and broader applications. NASA plans to continue the maturation of the GRX-810 alloy into component applications, with the final goal of commercialisation. Research efforts are said to be exploring additional applications within aerospace and the energy industry.

The full paper, “Extreme Temperature Additively Manufactured GRX-810 Alloy Development and Hot-fire Testing for Liquid Rocket Engines,” published by the American Institute of Aeronautics and Astronautics, can be downloaded here.

Download Metal AM magazine