NASA test fires additively manufactured aluminium rocket engine nozzle

November 1, 2023

NASA has reported the testing of additively manufactured aluminium rocket engine nozzles. Being lighter than traditional nozzles, the development is anticipated to pave the way for deep space missions capable of carrying larger payloads.

Under the agency’s Announcement of Collaborative Opportunity, engineers from NASA’s Marshall Space Flight Center in Huntsville, Alabama, partnered with Elementum 3D in Erie, Colorado, to develop a weldable type of aluminium that is heat resistant enough for use on rocket engines. Compared to other metals, aluminium has a lower density and allows for the creation of high-strength, lightweight components.

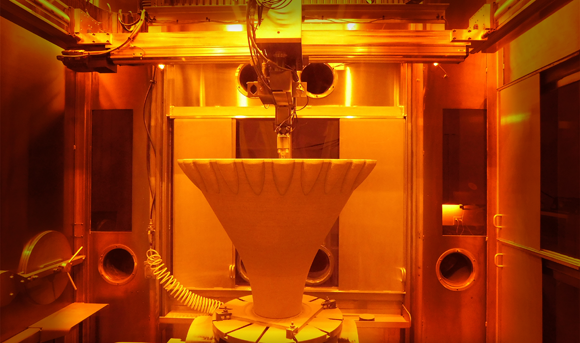

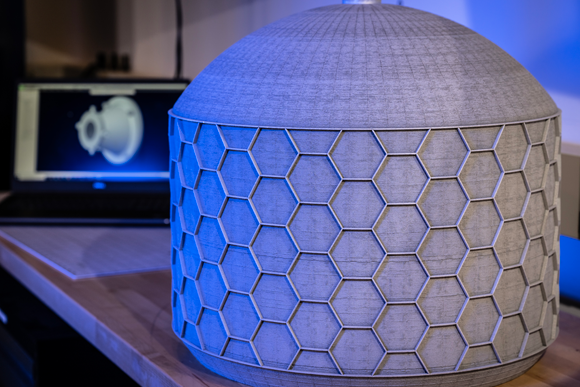

Due to its low tolerance to extreme heat and tendency to crack during welding, aluminium is not commonly used for Additive Manufacturing of rocket engine parts. However, NASA has made a recent development under the Reactive Additive Manufacturing for the Fourth Industrial Revolution (RAMFIRE) project. RAMFIRE, funded by NASA’s Space Technology Mission Directorate (STMD), aims to advance lightweight, additively manufactured aluminium rocket nozzles. These nozzles are designed with small internal channels to keep them cool enough to prevent melting.

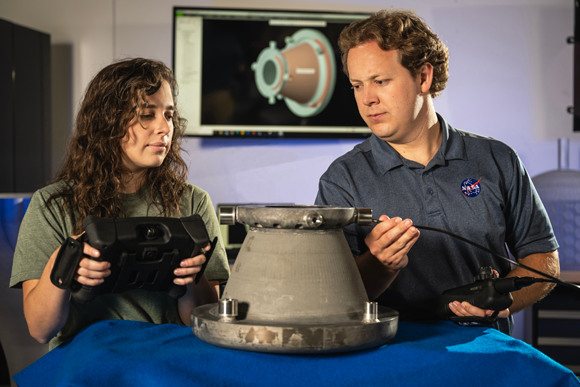

The RAMFIRE nozzle

With conventional manufacturing methods, a nozzle may require up to a thousand individually joined parts. In contrast, the RAMFIRE nozzle is constructed as a single piece, resulting in fewer bonds and significantly reduced manufacturing time.

NASA and Elementum 3D collaborated to develop a novel aluminium variant called A6061-RAM2. This variant was used to construct the nozzle and modify the powder used in laser Directed Energy Deposition (DED) Additive Manufacturing technology. RPM Innovations (RPMI), in Rapid City, South Dakota, utilised this newly invented aluminium and specialised powder to manufacture the RAMFIRE nozzles using its laser/powder-based Directed Energy Deposition process.

“Industry partnerships with specialty manufacturing vendors aid in advancing the supply base and help make Additive Manufacturing more accessible for NASA missions and the broader commercial and aerospace industry,” Paul Gradl, RAMFIRE principal investigator at NASA Marshall, shared.

“We’ve reduced the steps involved in the manufacturing process, allowing us to make large-scale engine components as a single build in a matter of days,” he continued.

NASA’s moon to Mars objectives necessitate the ability to transport a larger payload to deep space destinations. The alloy could be crucial in achieving this goal by allowing the production of lightweight rocket components that can withstand substantial structural loads.

“Mass is critical for NASA’s future deep space missions,” stated John Vickers, principal technologist for STMD advanced manufacturing. “Projects like this mature Additive Manufacturing along with advanced materials, and will help evolve new propulsion systems, in-space manufacturing, and infrastructure needed for NASA’s ambitious missions to the moon, Mars, and beyond.”

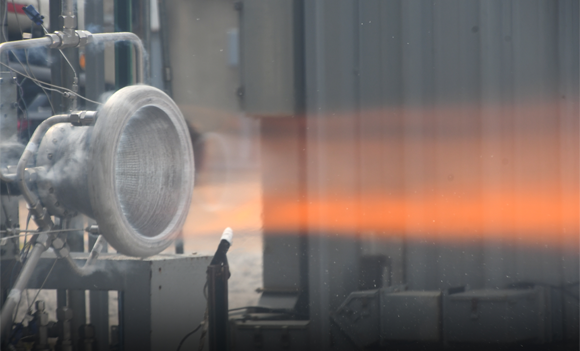

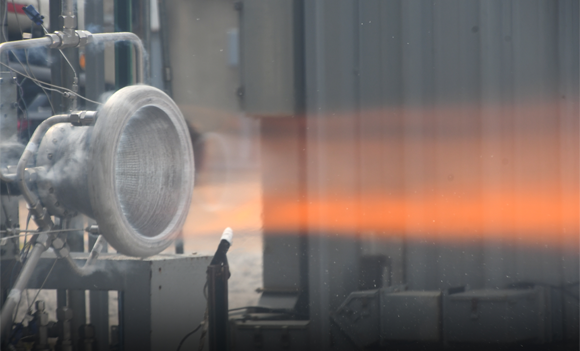

Earlier this summer, at Marshall’s East Test Area, two RAMFIRE nozzles underwent multiple hot-fire tests using different fuel configurations. These included liquid oxygen and liquid hydrogen, as well as liquid oxygen and liquid methane. Despite operating at pressures exceeding 825 pounds per square inch (psi), which exceeded the anticipated testing pressures, the nozzles performed successfully, completing twenty-two starts and accumulating a total run time of 579 seconds, or nearly ten minutes. This successful event demonstrates the nozzles’ ability to function effectively in the most challenging deep-space environments.

“This test series marks a significant milestone for the nozzle,” Gradl added. “After putting the nozzle through the paces of a demanding hot-fire test series, we’ve demonstrated the nozzle can survive the thermal, structural, and pressure loads for a lunar lander scale engine.”

The RAMFIRE project achieved success in building and testing rocket engine nozzles and also utilised the RAMFIRE aluminum material and Additive Manufacturing process to create additional advanced large components for demonstration purposes. These components include a 91.4 cm diameter aerospike nozzle with complex integral coolant channels and a vacuum-jacketed tank designed for cryogenic fluid applications.

NASA and industry partners are collaborating to share data and processes with commercial stakeholders and academia. Several aerospace companies are currently evaluating the novel alloy and the laser powder Directed Energy Deposition Additive Manufacturing process. They are exploring ways in which it can be utilised to manufacture components for satellites and other applications.

More can be seen here: https://youtu.be/CZgI622kYng

Download Metal AM magazine