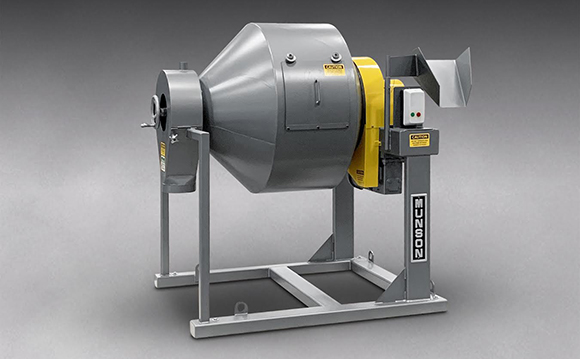

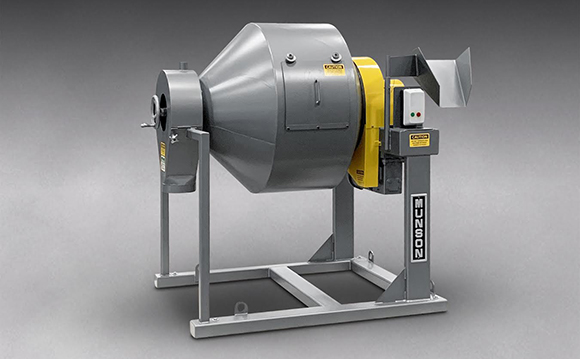

Munson Machinery introduces new abrasion-resistant rotary batch mini mixer for uniform blending

January 10, 2024

Munson Machinery, Utica, New York, USA, has introduced its new MX-10-AR abrasion-resistant Rotary Batch Mini Mixer. This mixer is able to blend up to 283 litres of aggregates, metal powders, pigments, sand, chemicals, and reinforced thermoplastics, with or without the addition of liquids, in ratios down to one part per million with total uniformity in two to three minutes.

The unit is reported to be equally efficient down to 15% (28 ℓ) of rated capacity, regardless of disparities in bulk densities, particle sizes or flow characteristics, making it suitable for laboratory testing, pilot production, or documenting outcomes when scaling up to larger rotary batch mixers.

The high-wear internal surfaces are made of abrasion-resistant steel, including proprietary mixing flights welded to the rotating drum. The flights gently tumble, turn, cut and fold the material, achieving homogeneous blends with no shear, while directing the entire batch toward and through a stationary plug gate valve with no residual waste or product segregation.

The mixer is equipped with a large access door and swing-away intake chute. It is powered by a worm-reducer to a chain and sprocket drive with enclosed drive guards as standard.

There are six models of Rotary Batch Mini Mixer with maximum batch capacities ranging from 7-425 litres. For larger-scale mixing, in-line Rotary Batch Mixers are available with maximum batch capacities ranging from 142 litres to 17 cubic metres.

Download Metal AM magazine