MULTI-FUN project to enable multi-material metal AM

July 14, 2020

A consortium of twenty-one partners from eight countries has established MULTI-FUN, a three-year project to enable multi-material and multi-functional metal Additive Manufacturing of complex parts. The project aims to broaden the scope for metal Additive Manufacturing, and will leverage nanotechnologies to improve heat transfer rates, achieve higher complexity of internal design and enable the inclusion of sensing and data transfer capabilities.

A total of four science and technology objectives have been identified. The first is the development of five new materials customised for AM, with three of these using nanotechnology. This is said to allow for the creation of new products by maximising thermal conductivity, minimising electrical conductivity and/or improving the wear resistance of the metals.

The second objective is the development of new equipment and software to additively manufacture the new material compositions. It is expected that this will result in innovative equipment that integrates several AM technologies working in parallel.

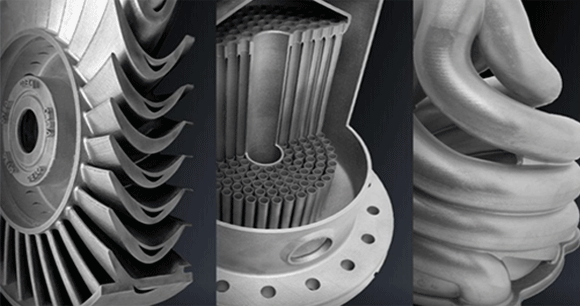

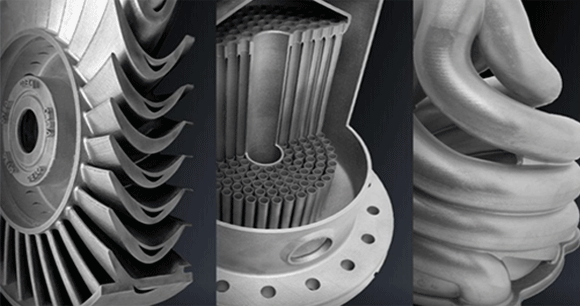

The third objective is the manufacture and evaluation of physical demonstrator parts, with multi-material design and integrated multi-functionalities. At least ten new material combinations, from the five new materials, will be used to produce seven demonstrator parts aimed at different applications. These will include structural parts, moulds and test equipment, addressing the automotive, aviation, space and production industry sectors.

The final objective relates to constant assessment and improvement through a feedback loop, helping to reduce environmental and economic impact by evaluating AM materials, hardware, process strategy and part design. The expected key result from this will be the development of new standards and support the adoption of multi-material Additive Manufacturing.

The MULTI-FUN project has received funding from the European Union’s Horizon 2020 research and innovation programme.