MT Aerospace acquires second DED AM machine from AddUp

November 10, 2022

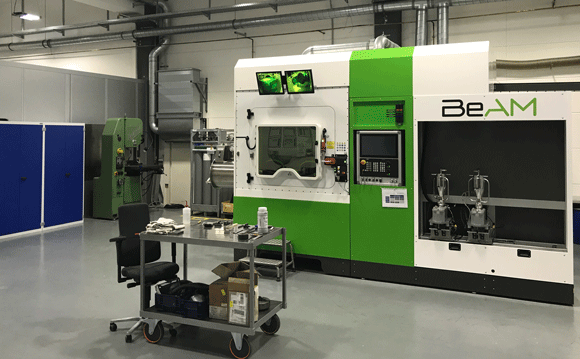

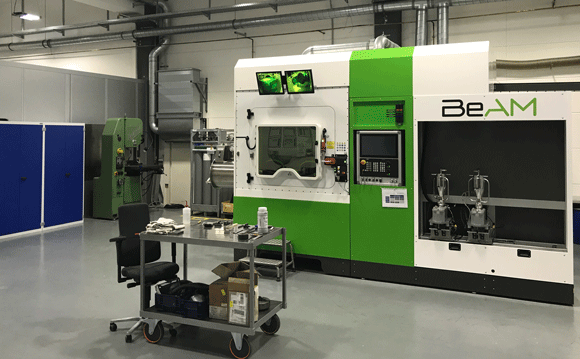

MT Aerospace AG, Augsburg, Germany, a subsidiary of the space and technology group OHB SE, has acquired a second Modulo 400 Directed Energy Deposition (DED) Additive Manufacturing machine from AddUp, headquartered in Cébazat, France. The addition of the second AM machine will enable MT Aerospace to multiply projects while reducing industrialisation times, as well as moving towards using this technology for series production.

MT Aerospace is a leading provider of fluid storage for the aerospace industry and designs and manufactures fuel tanks for satellites and space launchers, including the Ariane 5 programme. The company is also the main supplier of drinking water and wastewater storage systems for Airbus group aircraft. Specialising in metal and composite processing, MT Aerospace also has experience in metal AM, particularly the DED process, thanks to its Modulo 400 AM machine supplied by AddUp in 2020.

MT Aerospace states that it will be able to take advantage of the doubled production capacity to work simultaneously in several directions. First, the acceleration of qualification phases for satellites fuel tanks in collaboration with the European Space Agency, as well as the development of new applications for satellites and micro-launchers. Secondly, the second Modulo 400 AM machine will be an opportunity to expand services and address other sectors, such as the automotive or energy industries.

AddUp has been working closely with MT Aerospace for the past two years to qualify applications using the DED process. The company states that the Modulo 400 machine, which sprays metal powders through a high-powered laser beam, has proven its ability to create parts with fine surface finishes and high mechanical characteristics. MT Aerospace has already tested it on a wide variety of materials, including reactive materials such as titanium thanks to the high level of safety of the machine.

MT Aerospace is preparing to build up a complete industrial platform around DED technology, with design skills and production, post-processing, and part inspection capabilities. All these activities are expected to be compatible with the requirements of the EN 9100 standard applicable to the aerospace sector.

AddUp and MT Aerospace will be presenting parts made through their partnership at Formnext which takes place in Frankfurt, Germany, from November 15–18. They will be located in Hall 12.0, booth E01.