ModuleWorks MDES designed to connect different technologies across software and hardware systems

September 19, 2023

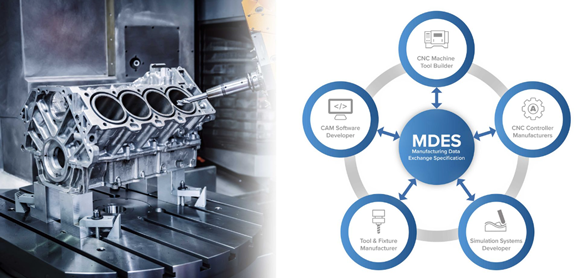

ModuleWorks GmbH, Aachen, Germany, has announced that its Manufacturing Data Exchange Specification (MDES) has been adopted by Autodesk and DN Solutions (formally known as Doosan Machine Tools). The concept of MDES is to bring more value to the manufacturing industry by connecting different technologies across software and hardware systems.

ModuleWorks introduced MDES as an open specification for exchanging digital representations of manufacturing equipment between various hardware and software systems across multiple process steps. This covers tool components, assemblies, fixtures, stocks, setups, and their mounting in machine tools. With MDES, ModuleWorks aims to facilitate the formation of an open ecosystem that can be used by any company to efficiently exchange machining data between different hardware and software platforms.

“It is a pleasure to see two leading software and hardware innovators validate the impact MDES can have on the industry and their trust in ModuleWorks as a steward of this open specification,” stated Dr Yavuz Murtezaoglu, Founder & Managing Director of ModuleWorks. “As a neutral software provider, we are committed to our partners for the fast-paced development of software components for CAD/CAM system developers, CNC Controller Manufacturers and Machine Tool Builders. With MDES, we extend our commitment to any manufacturing stakeholder who can benefit from simplifying manufacturing data exchange and reducing barriers to software adoption.”

Autodesk is a Strategic Partner of ModuleWorks and has integrated ModuleWorks toolpath technology into its Fusion 360® CAD software. The early adoption of MDES enables Fusion 360 users to output MDES data, providing additional information for the machining process and reducing setup time on the CNC machine.

“From inception, our intent with Fusion has been a platform that brings cloud technology’s advancements to all the people, machines and software involved in the design and manufacturing process,” said Al Whatmough, Director, Product Design and Manufacturing Solutions, Autodesk. “We’re eliminating bottlenecks that reduce accurate and effective communication. Smarter machines on the shop floor, using CAM data, will yield better outcomes when they understand an operator’s intent, rather than just blindly follow commands.”

“The MDES open standard is the major step the industry needs toward improving the problematic communication between CAM software and machine tools. We’re excited to see this new standard enable companies like DN Solutions to offer machines that further increase manufacturing productivity,” Whatmough concluded.

Download Metal AM magazine