Modular prototype production with metal Additive Manufacturing enables faster gas turbine development

July 8, 2016

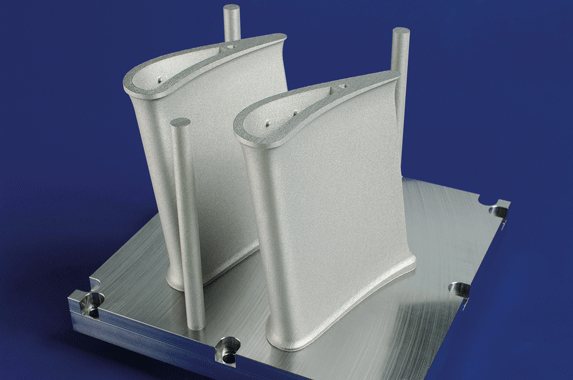

Individually manufactured segments of the guide vanes for the modular process chain (material: Inconel® 718).

A joint project between Siemens and the Fraunhofer Institute for Laser Technology ILT in Germany is reported to have resulted in a production process, based around selective laser melting (SLM), which significantly shortens the development time of new gas turbine blades and vanes.

The report states that conventional vane production, through casting, is unsuited for the fast iteration cycles now required in the development of hot path components. The long lead time of turbine blades and vanes presents a big challenge to the validation of new part designs in engine tests.

During the test stages, individual turbine parts are exposed to temperatures of 1500 C or more. Such components are traditionally manufactured from superalloys in a precision casting process, in which each iterative loop may last several months and incur significant costs. Thus far, this has severely curtailed the number of tests possible.

The authors state that components can now be manufactured in a modular way in the new process chain, resulting in numerous benefits.

To withstand the high temperatures over long periods of time, the turbine vanes require complex internal cooling structures. Selective laser melting has proven itself to be up to the challenge, especially for prototypes or small batches featuring complex geometries.

Over the past several years, Fraunhofer ILT states that it has built up considerable expertise in the use of additive laser techniques and alloys for components exposed to high temperatures. Scientists were able to develop special processes that made it possible to produce the relatively large parts (up to 250 mm) at Siemens with a high degree of dimensional accuracy and superior surface quality.

Guide vanes made using the new modular process chain (material: Inconel® 718)

Securely mounted on the turbine housing, guide vanes channel the hot gas to the movable rotor blades. The guide vanes consist of two massive platforms plus an airfoil with a delicate cooling structure. The latter presents a major manufacturing challenge as even production using SLM required additional internal supports.

A modified process chain has solved the problem: the platforms and the airfoil are manufactured separately and then subsequently brazed together. This makes it possible to not only eliminate the supports in the blade, but also to improve the surface quality. The result is a fully functional component that can be used in hot path rig testing in order to deliver quick feedback to the design engineers.

Siemens optimized various production steps in preparation for this idea. After manufacturing via laser, the parts are precisely measured, subjected to finishing, and then joined using high temperature brazing.

This modular production of turbine blades offers significant potential for other components as well, the authors state. It would make it possible to connect cast and SLM-made parts, leaving just the complex or variable parts to be produced using SLM. At the same time, it would also facilitate the production of parts with difficult geometries that are currently too large for the SLM process.