Michelin adds sixth FormUp 350 for the production of tyre molds

March 5, 2024

Michelin Molding Solutions (MMS), based in Greenville, South Carolina, USA, has purchased its second FormUp 350 Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing machine from AddUp SAS, headquartered in Cébazat, France. The new machine represents the sixth to be added to Michelin’s expanding global fleet of FormUp AM machines, currently in use across Europe and North America.

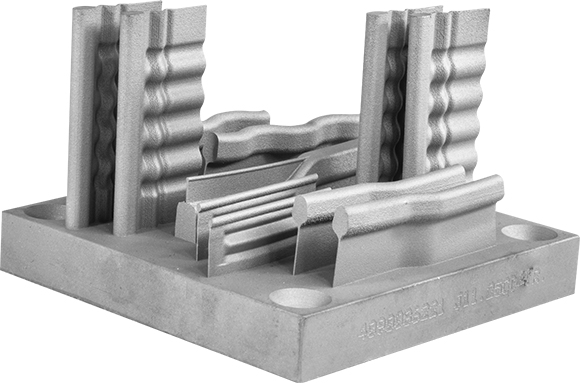

MMS is Michelin’s worldwide division for production of tyre curing molds. From locations in Europe, Asia and North America, MMS supplies molds to Michelin’s tyre manufacturing plants throughout the world. The complex tyre geometries demanded by Michelin to deliver superior tyre performance require equally complex mold geometries which can’t always be produced with traditional manufacturing processes. For almost twenty years, MMS has used metal Additive Manufacturing to meet those demands.

“MMS is very pleased with the productivity and quality achievable on AddUp’s FormUp 350. This level of productivity allowed us to decommission older and less productive 3D printers. We’ve seen improvements in the cleanliness and safety of our operations and our operators very much appreciate its ease of use from build plate programming to machine set up and the machine user interface,” explained Glen Nelson, Technical Development Manager at MMS.

One FormUp 350 can reportedly manufacture the quantity of tyre mold inserts which previously required five metal Additive Manufacturing machines and can achieve it faster and more reliably. By using metal AM, MMS has reportedly been able to produce millions of mold sipe inserts over the past two decades, with increasingly sophisticated shapes, to improve traction and wear over the life of the tyre.

Download Metal AM magazine