Metshape’s micro metal AM used for microgravity capillary action experiment

January 18, 2023

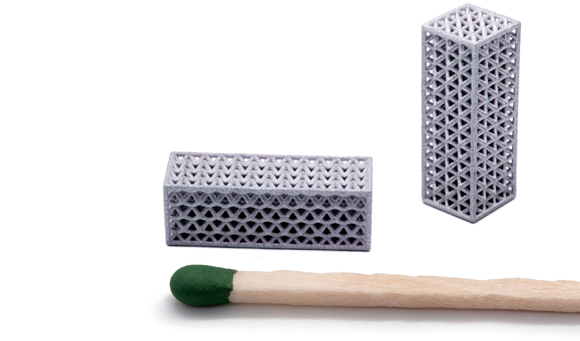

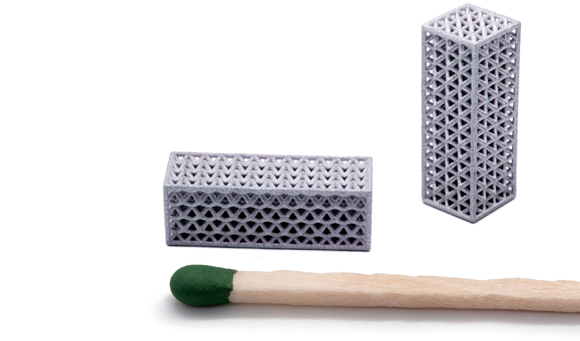

A team of students from the International Space Station Research (ISS) Lab Program at Valley Christian High School (VCS), San Jose, California, USA, has used Additive Manufacturing to produce millimeter-scale lattices for an experiment on capillary action in microgravity.

With struts as thin as 0.5 mm in diameter, the metal structure was not thought suitable for conventional Powder Bed Fusion or Binder Jetting technologies, so the team turned to Qualified3D, a distributor of Germany’s Metshape GmbH high-precision Vat Photopolymerisation (VPP) manufacturing services, a process the company refers to as Lithography-based Metal Manufacturing (LMM).

This technology is reportedly capable of producing parts with extremely thin walls (125 µm) and smooth surfaces (2-5 µm surface roughness before polishing) in a variety of metals, including stainless steel and titanium.

“Some of our students discovered that the miniature lattice design was printable using the LMM technology and proactively reached out to them,” stated Emeka Okekeocha, ISS Program Manager at VCS. “After a technical review, we accepted the proposed change from acrylate resin to stainless steel.”

The students in the ISS Research Lab received their parts within a few weeks and now intend to put them to use for their experiment in microgravity. The experiment package should be launched to the ISS in mid-February 2023 and should begin returning data in March.

David Kou, a member of the team at VCS added, “We are very thankful to Qualified3D for how they always quickly responded to our requests and questions. Even with the many changes we requested, the parts were still delivered on time, which helped us to transition smoothly between planning and building our microgravity experiment.”

On a broader level, controlled capillarity in additively manufactured metallic lattices is hoped to open new technical possibilities in future outer space applications such as gas filtration, aerosol sample collection, and temperature management. Another application is being able to passively control the position of water in a container, since, without this technology, it would be difficult to predict the location of the water in applications such as plant growth, for example.